Page 150 - All Industrial Tool Supply | General Catalog

P. 150

DRILLS • Cobalt Jobbers

148

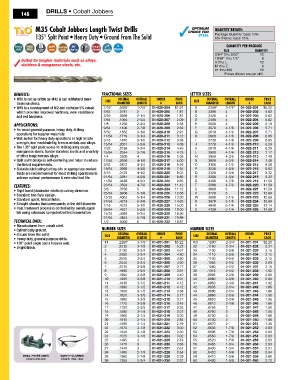

M35 Cobalt Jobbers Length Twist Drills QuanTiTy BreakS:

135° Split Point • Heavy Duty • Ground From The Solid Package Quantity: Less 10%

60+ Pieces: Less 15%

QuanTiTy Per PaCkage

Size QuanTiTy

3/64" thru 9/32" 12

Suited for tougher materials such as alloys, 19/64" thru 1/2" 6

stainless & manganese steels, etc. A thru L 12 6

M thru Z

#1 thru #60 12

Prices shown are per drill.

Benefits: FraCTiOnaL SizeS LeTTer SizeS

• M35 is not as brittle as M42 & can withstand more DeCiMaL OveraLL OrDer PriCe DeCiMaL OveraLL OrDer PriCe

torsional stress. Size DiaMeTer LengTh # eaCh Size DiaMeTer LengTh # eaCh

• M35 is a development of M2 and contains 5% cobalt 1/16" .0625" 1-7/8" 01-020-204 $1.91 A .2340" 3-7/8" 01-022-201 $5.22

which provides improved hardness, wear resistance 5/64 .0781 2 01-020-205 1.87 B .2380 4 01-022-202 5.62

and red hardness. 3/32 .0938 2-1/4 01-020-206 1.87 C .2420 4 01-022-203 5.62

7/64 .1094 2-5/8 01-020-207 2.09 D .2460 4 01-022-204 5.62

APPLiCAtiOns: 1/8 .1250 2-3/4 01-020-208 2.58 E .2500 4 01-022-205 5.13

• For most general purpose, heavy duty, drilling 9/64 .1406 2-7/8 01-020-209 2.62 F .2570 4-1/8 01-022-206 5.71

operations for tougher materials. 5/32 .1562 3-1/8 01-020-210 2.91 G .2610 4-1/8 01-022-207 5.71

• Well suited for heavy duty operations in high tensile 11/64 .1719 3-1/4 01-020-211 3.12 H .2660 4-1/8 01-022-208 6.05

3/16

6.05

3.38

01-022-209

I

.1875

4-1/8

3-1/2

01-020-212

.2720

strength, low machinability, ferrous metals and alloys. 13/64 .2031 3-5/8 01-020-213 4.09 J .2770 4-1/8 01-022-210 6.29

• The 135° split point works for drilling alloy steels, 7/32 .2188 3-3/4 01-020-214 4.45 K .2810 4-1/4 01-022-211 6.29

manganese steels, harder stainless steels and a variety 15/64 .2344 3-7/8 01-020-215 4.73 L .2900 4-1/4 01-022-212 7.17

of other tough ferrous alloys. 1/4 .2500 4 01-020-216 5.08 M .2950 4-3/8 01-022-213 7.48

• Split point design is self-centering and helps to reduce 17/64 .2656 4-1/8 01-020-217 6.00 N .3020 4-3/8 01-022-214 7.48

the thrust requirements. 9/32 .2812 4-1/4 01-020-218 6.26 O .3160 4-1/2 01-022-215 8.39

• Suitable lubricating/cutting oils or appropriate coolant 19/64 .2969 4-3/8 01-020-219 7.54 P .3230 4-5/8 01-022-216 8.82

fluids are recommended for most drilling operations to 5/16 .3125 4-1/2 01-020-220 8.03 Q .3320 4-3/4 01-022-217 9.32

achieve optimal performance & extended tool life. 21/64 .3281 4-5/8 01-020-221 6.85 R .3390 4-3/4 01-022-218 9.32

11/32 .3438 4-3/4 01-020-222 9.65 S .3480 4-7/8 01-022-219 11.59

feAtures: 23/64 .3594 4-7/8 01-020-223 11.42 T .3580 4-7/8 01-022-220 11.59

• Right hand (clockwise rotation) cutting direction. 3/8 .3750 5 01-020-224 11.12 U .3680 5 01-022-221 11.59

• Standard two flute design. 25/64 .3906 5-1/8 01-020-225 12.66 V .3770 5 01-022-222 12.69

• Standard spiral, helical flutes. 13/32 .4062 5-1/4 01-020-226 13.30 W .3860 5-1/8 01-022-223 12.69

.3970

X

5-1/8

12.69

14.63

01-020-227

5-3/8

01-022-224

.4219

27/64

• Straight shanks that corresponds to the drill diameter. 7/16 .4375 5-1/2 01-020-228 15.00 Y .4040 5-1/4 01-022-225 13.14

• Heat treatment process is controlled by metallurgical 29/64 .4531 5-5/8 01-020-229 18.00 Z .4130 5-1/4 01-022-226 14.58

lab using advanced computerized instrumentation. 15/32 .4688 5-3/4 01-020-230 18.36

31/64 .4844 5-7/8 01-020-231 19.89

teChniCAL DAtA: 1/2 .5000 6 01-020-232 18.87

• Manufactured from cobalt steel.

• Cylindrically ground. nuMBer SizeS nuMBer SizeS

• Ground from the solid. Size DeCiMaL OveraLL OrDer PriCe Size DeCiMaL OveraLL OrDer PriCe

• Heavy duty, general purpose drills. DiaMeTer LengTh # eaCh DiaMeTer LengTh # eaCh

• 135° point angle and a heavier web. #1 .2280" 3-7/8" 01-021-201 $5.22 #31 .1200" 2-3/4" 01-021-231 $2.26

• Bright finish. 2 .2210 3-7/8 01-021-202 5.22 32 .1160 2-3/4 01-021-232 2.31

3 .2130 3-3/4 01-021-203 4.67 33 .1130 2-5/8 01-021-233 2.15

4 .2090 3-3/4 01-021-204 4.90 34 .1110 2-5/8 01-021-234 2.15

5 .2055 3-3/4 01-021-205 4.90 35 .1100 2-5/8 01-021-235 2.15

6 .2040 3-3/4 01-021-206 4.90 36 .1065 2-1/2 01-021-236 2.03

7 .2010 3-5/8 01-021-207 3.77 37 .1040 2-1/2 01-021-237 2.15

8 .1990 3-5/8 01-021-208 3.91 38 .1015 2-1/2 01-021-238 1.92

9 .1960 3-5/8 01-021-209 4.40 39 .0995 2-3/8 01-021-239 2.00

10 .1935 3-5/8 01-021-210 3.91 40 .0980 2-3/8 01-021-240 2.00

11 .1910 3-1/2 01-021-211 4.12 41 .0960 2-3/8 01-021-241 1.92

12 .1890 3-1/2 01-021-212 4.12 42 .0935 2-1/4 01-021-242 1.86

13 .1850 3-1/2 01-021-213 3.58 43 .0890 2-1/4 01-021-243 1.86

14 .1820 3-3/8 01-021-214 3.77 44 .0860 2-1/8 01-021-244 1.86

15 .1800 3-3/8 01-021-215 3.77 45 .0820 2-1/8 01-021-245 1.86

16 .1770 3-3/8 01-021-216 3.45 46 .0810 2-1/8 01-021-246 1.86

17 .1730 3-3/8 01-021-217 3.33 47 .0785 2 01-021-247 1.86

18 .1695 3-1/4 01-021-218 3.07 48 .0760 2 01-021-248 1.86

19 .1660 3-1/4 01-021-219 3.00 49 .0730 2 01-021-249 1.86

20 .1610 3-1/4 01-021-220 2.84 50 .0700 2 01-021-250 1.86

21 .1590 3-1/4 01-021-221 2.79 51 .0670 2 01-021-251 1.86

22 .1570 3-1/8 01-021-222 3.00 52 .0635 1-7/8 01-021-252 2.03

23 .1540 3-1/8 01-021-223 3.30 53 .0595 1-7/8 01-021-253 2.03

24 .1520 3-1/8 01-021-224 3.02 54 .0550 1-7/8 01-021-254 2.03

25 .1495 3 01-021-225 2.74 55 .0520 1-7/8 01-021-255 2.03

26 .1470 3 01-021-226 2.66 56 .0465 1-3/4 01-021-256 2.03

27 .1440 3 01-021-227 2.67 57 .0430 1-3/4 01-021-257 2.51

28 .1405 2-7/8 01-021-228 2.54 58 .0420 1-5/8 01-021-258 2.84

drill press vises safety glasses 29 .1360 2-7/8 01-021-229 2.39 59 .0410 1-5/8 01-021-259 2.66

PAGES 838-839 PAGES 1594-1600 30 .1285 2-3/4 01-021-230 2.31 60 .0400 1-5/8 01-021-260 2.72