Roemheld Robust Swing Clamps-Flange Base

5000 psi maxDouble Acting

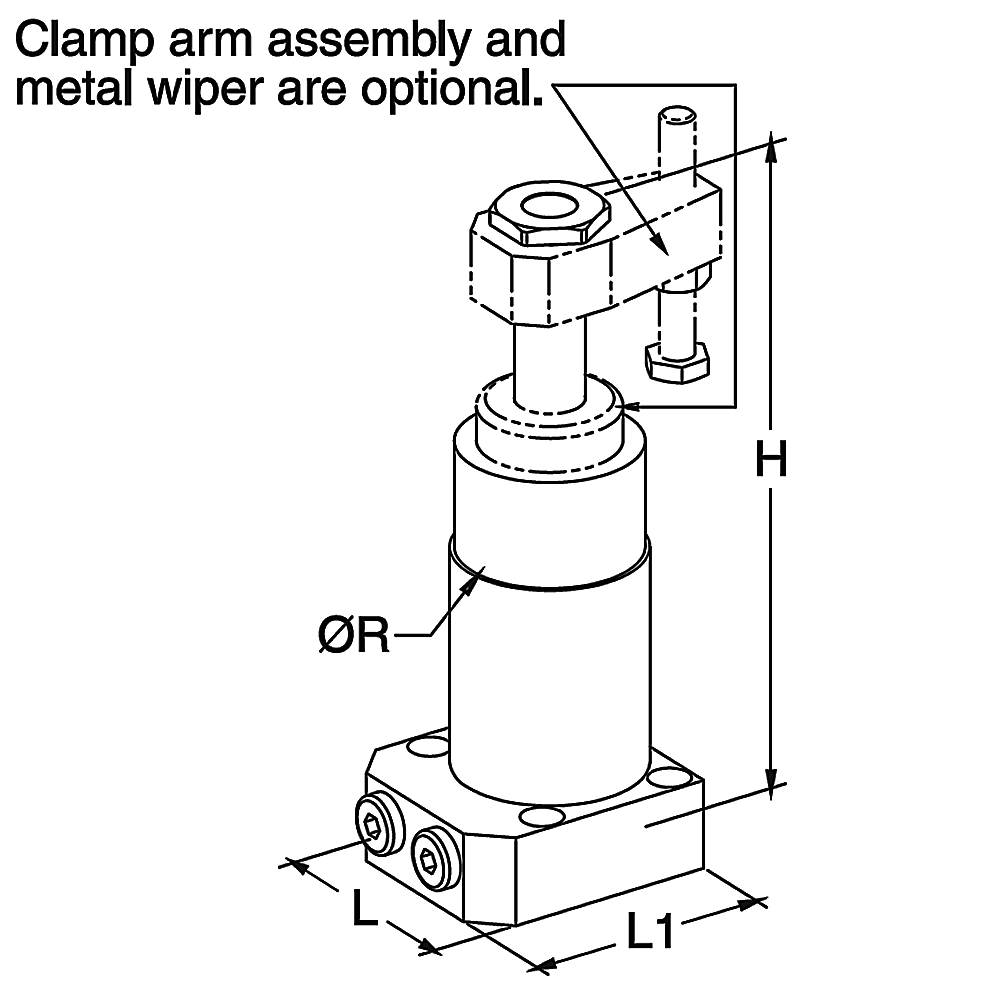

Swing Clamps utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. The Robust Swing Clamps shown here are compact, economical, heavy-duty clamps with a reinforced swing mechanism and a heavier clamping arm to exert high clamping force in relation to clamp size-especially important at lower operating pressures (450 to 5000 psi operating range). Robust Swing Clamps are also ideal when using longer, heavier custom arms. An integral flow-control orifice allows using high-flow-rate power sources without separate flow restrictors. Arm can be mounted to start its 90° swing from any position within 360°. The flange-base version provides many plumbing options, including manifold mounting.

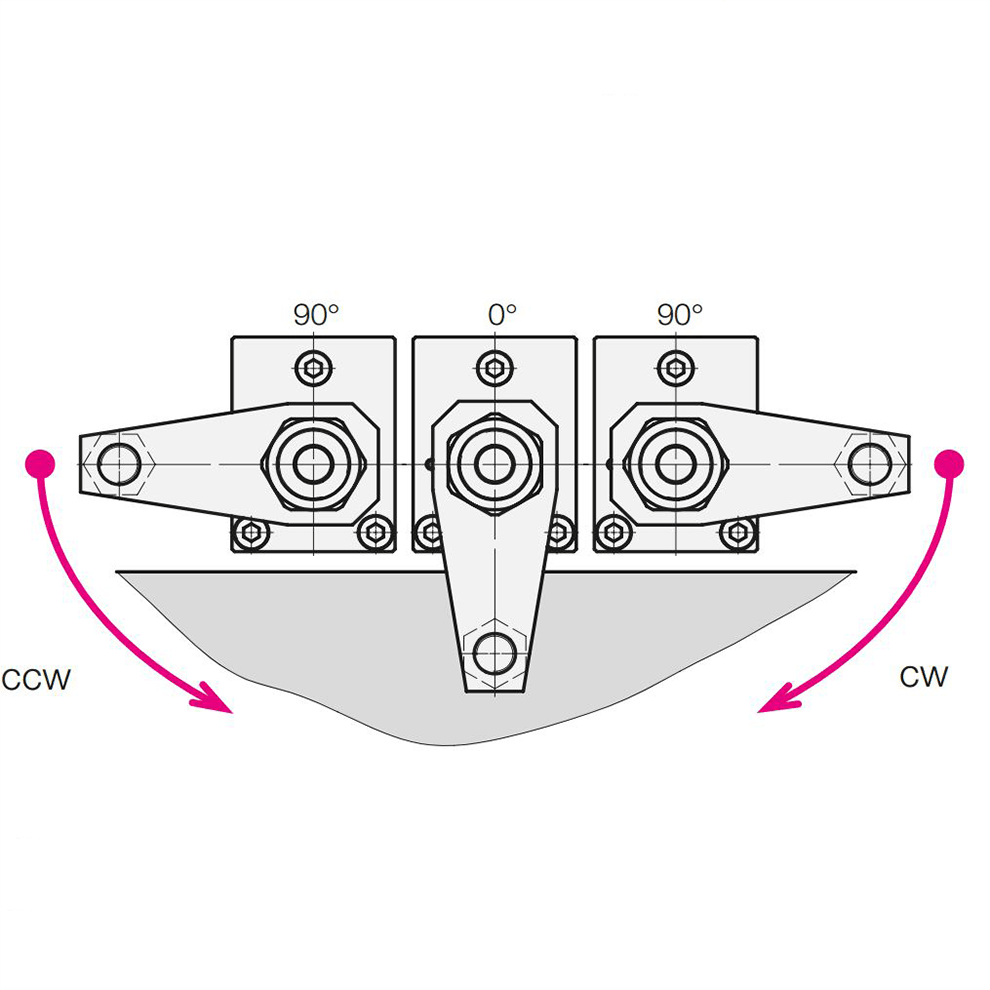

Clamping Action

Swing Clamps are pull-type cylinders where part of the total stroke is used to swing the piston, and the remaining stroke is available as the clamping range. Applying fluid pressure to the A (clamping) port swings arm 90° over workpiece then clamps down. Switching pressure to the B (unclamping) port positively lifts arm then swings it back 90° for loading/unloading.

Reinforced Swing Mechanism

Reinforced swing mechanism ensures positive arm position. The safety-clutch mechanism normally incorporated into the swing clamps is omitted in this design. In case the workpiece hits the clamping arm during loading, the angular position of the swing-clamp arm will be exactly maintained. Using a longer, heavier clamping arm will also not declutch the swing arm and affect arm position.

Mounting & Fluid Supply

Dual mounting capability allows any clamp to be mounted using standard fittings or manifold mounting. Two 1/4" BSPP ports. For optional manifold mounting, use the O-ring ports underneath, instead of the standard ports. Do not use NPT fittings. For manifold mounting, the mounting surface must be ground flat to ensure proper O-ring sealing. Fasten clamp with four socket-head cap screws.

Optional Position Monitoring

An accessory unit for pneumatic position control is available to monitor that the Swing Clamp is in "clamped" position. This simple, reliable unit consists of a stainless steel housing with a spring-loaded control tappet. To operate the tappet, a control bracket must be attached to the rear of the clamping arm. This bracket must be adjusted so that it first contacts the tappet during the downward clamping stroke, after the full swing stroke, at a height where it will not bottom out on the housing at full clamping stroke. When the clamping arm reaches "clamped" position, the pressure control is closed and the pressure built up at the pneumatic port can be evaluated with a differential pressure switch. Parallel connection of up to three controls is possible with a single differential switch.

Optional Metalic Wiper

This optional, additional wiper protects the FKM wiper against physical damage, e.g. by hot chips. These Swing Clamps are ready for mounting the metallic wiper, which consists of a radially floating wiping disk and a retaining disk which is pressed onto the existing collar.

Material

Piston > Alloy steel, nitrated for wear and corrosion resistance. Housing > Mild steel, nitrated for wear and corrosion resistance. Piston rod wiper > FKM. DFARS and RoHS compliant.

Parts Specification

| Clamp Size | Swing Direction | Maximum Clamping Force (lbs) | Maximum Clamping Force (kn) | H (mm) | L (mm) | L1 (mm) | R Diameter (mm) | Clamping Stroke (mm) | Total Stroke (mm) |

| 3 Series | 0° | 1300 lbs. | 5.9 kN | 162.3mm | 55mm | 60mm | 45mm | 12mm | 23mm |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

844.548.0100

844.548.0100

Quotes

Quotes

Quick Order

Quick Order