Roemheld Standard Swing Clamps-Top Flange

3000 to 7250 psi maxSingle and Double Acting

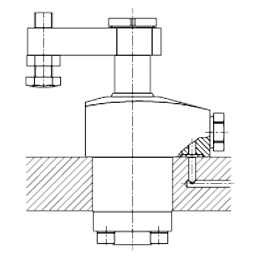

Swing Clamps utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. The Standard Swing Clamps shown here accept a wide variety of clamping arms, with maximum allowable operating pressure depending on the type of arm selected (3000 to 7250 psi max). These Swing Clamps incorporate the unique safety-clutch mechanism. If the clamping arm strikes an unexpected object during its swing, the clutch disengages to avoid damaging the object or the clamp's helical-cam mechanism. Clamping arm can be mounted to start its 90° swing from any position within 360°. The top-flange version allows low-profile installation. Dual mounting capability provides every clamp with the option of using either standard fittings or manifold mounting.

Application Information

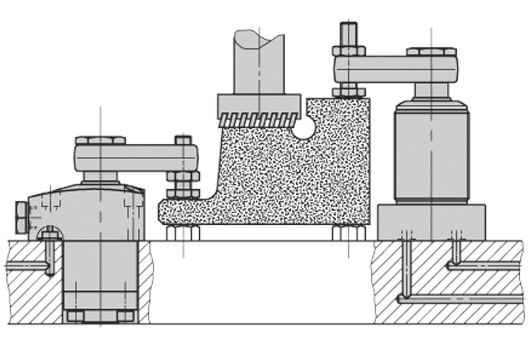

Top-flange swing clamp used together with a flange-base swing clamp to clamp at different heights. Both clamps are manifold mounted, with fluid passages in the base plate.

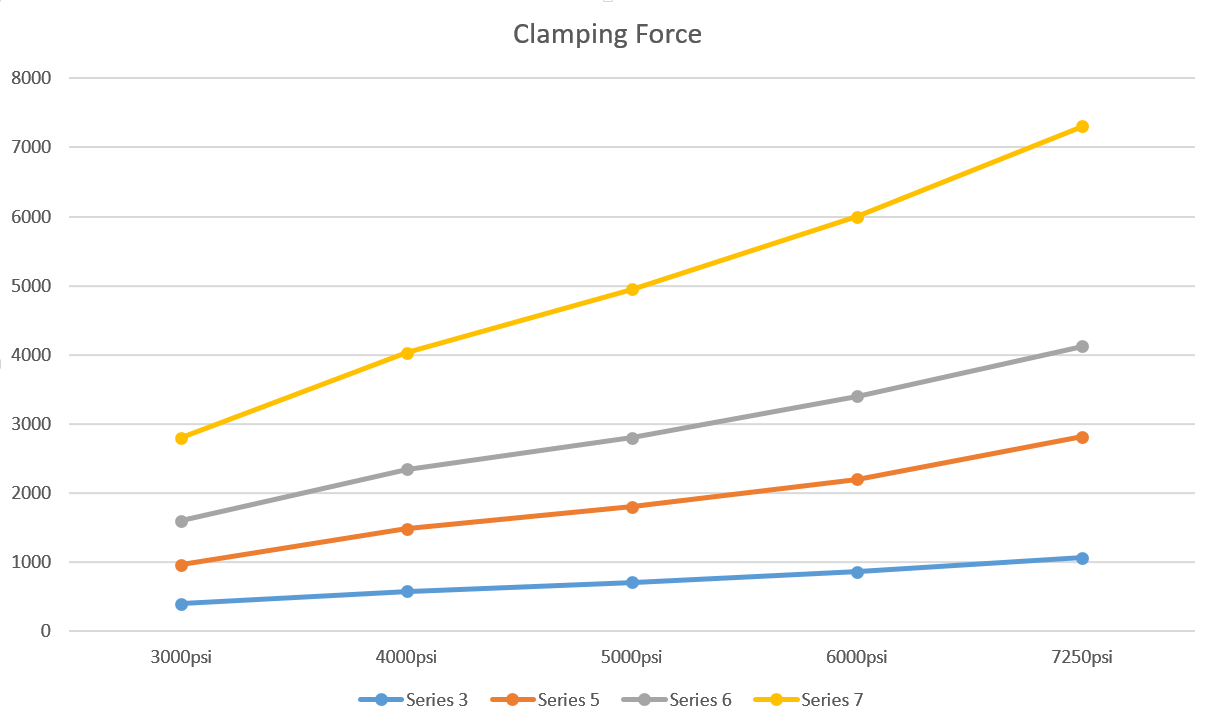

Sizes & Clamping Force

Clamping force with Pivoting Arm

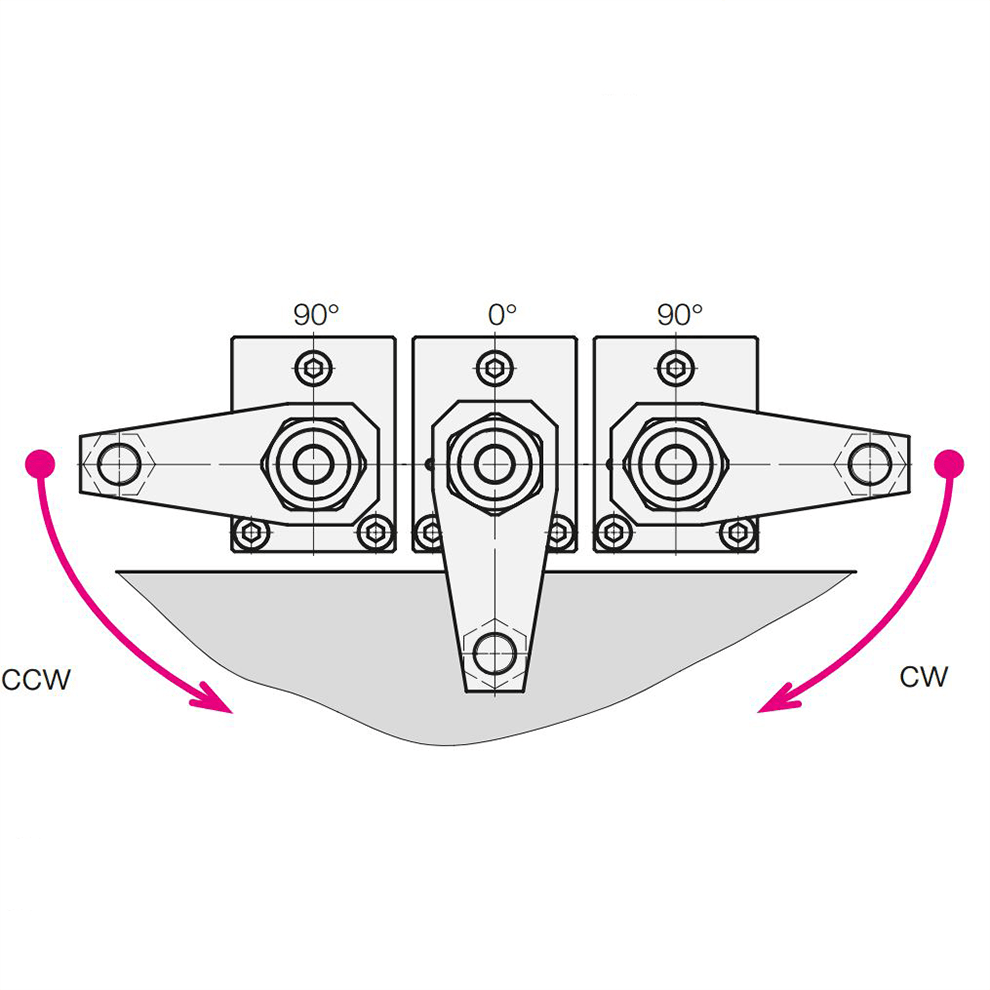

Clamping Action

Swing Clamps are pull-type cylinders where part of the total stroke is used to swing the piston, and the remaining stroke is the clamping range. Applying fluid pressure swings arm 90° over workpiece then clamps down. Single-acting version has a fast, totally dependable spring return that lifts arm then swings it back 90° for loading/unloading. Optional fluid return (double acting).

Design Considerations

These Swing Clamps incorporate the unique safety-clutch mechanism. If the clamping arm strikes an unexpected object during its swing, the clutch disengages to avoid damaging the object or the clamp's helical-cam mechanism. For extended clamp life and proper operation of the safety clutch, a simple flow-control valve may be required if the fixture is powered by a high-flow-rate power source and only contains a few clamps. Clamping time should be at least one second.

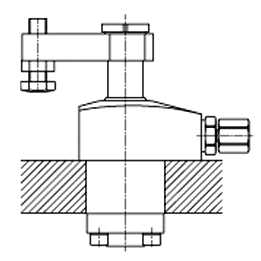

Mounting & Fluid Supply

Standard Fittings

Manifold Mounting

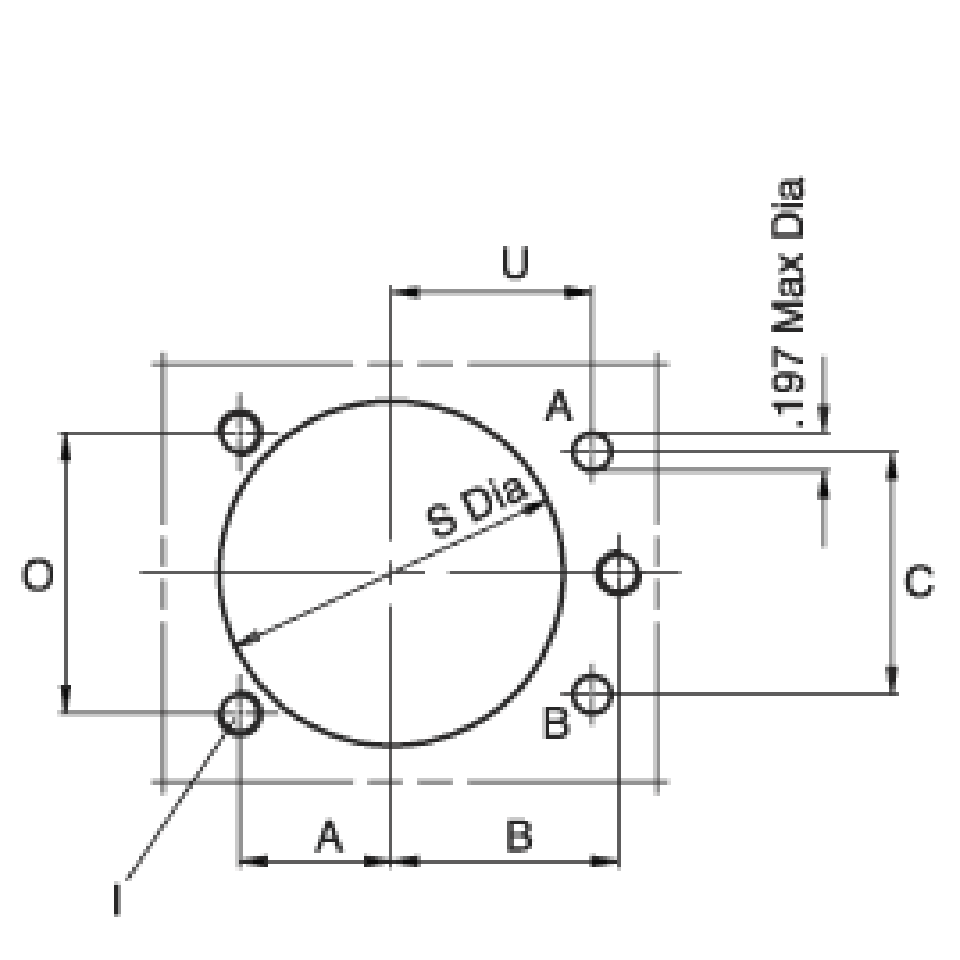

Fasten clamp with three socket-head cap screws. Dual mounting capability provides every clamp with the option of using either standard fittings or manifold mounting. 1/4" BSPP port (two for double-acting clamps). Do not use NPT fittings.For optional manifold mounting, use the O-ring port underneath, instead of the standard port (two for double-acting clamps). For manifold mounting, the mounting surface must be ground flat to ensure proper O-ring sealing. Unscrew the sealing plug in each O-ring port.

Material

Piston > Alloy steel, nitrated for wear and corrosion resistance. Housing > Mild steel, nitrated for wear and corrosion resistance. Piston rod wiper > Viton.

Parts Specification

| Clamp Size | Swing Direction | Maximum Clamping Force (lbs) | Maximum Clamping Force (kn) | Length (mm) | Width (mm) | Height (mm) | Clamping Stroke (mm) | Total Stroke (mm) |

| 6 Series | 90° cw | 4500 lbs. | 20 kN | 110mm | 85mm | 172mm | 15mm | 26mm |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

844.548.0100

844.548.0100

Quotes

Quotes

Quick Order

Quick Order