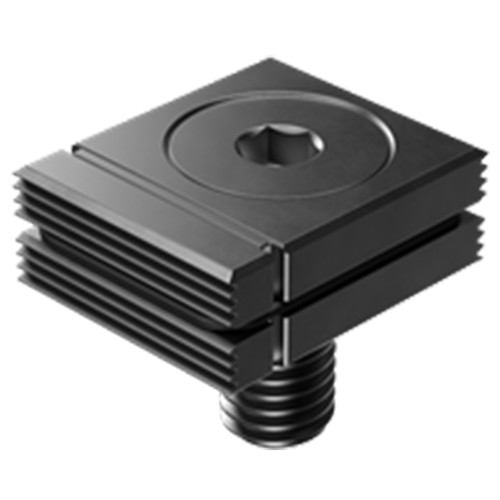

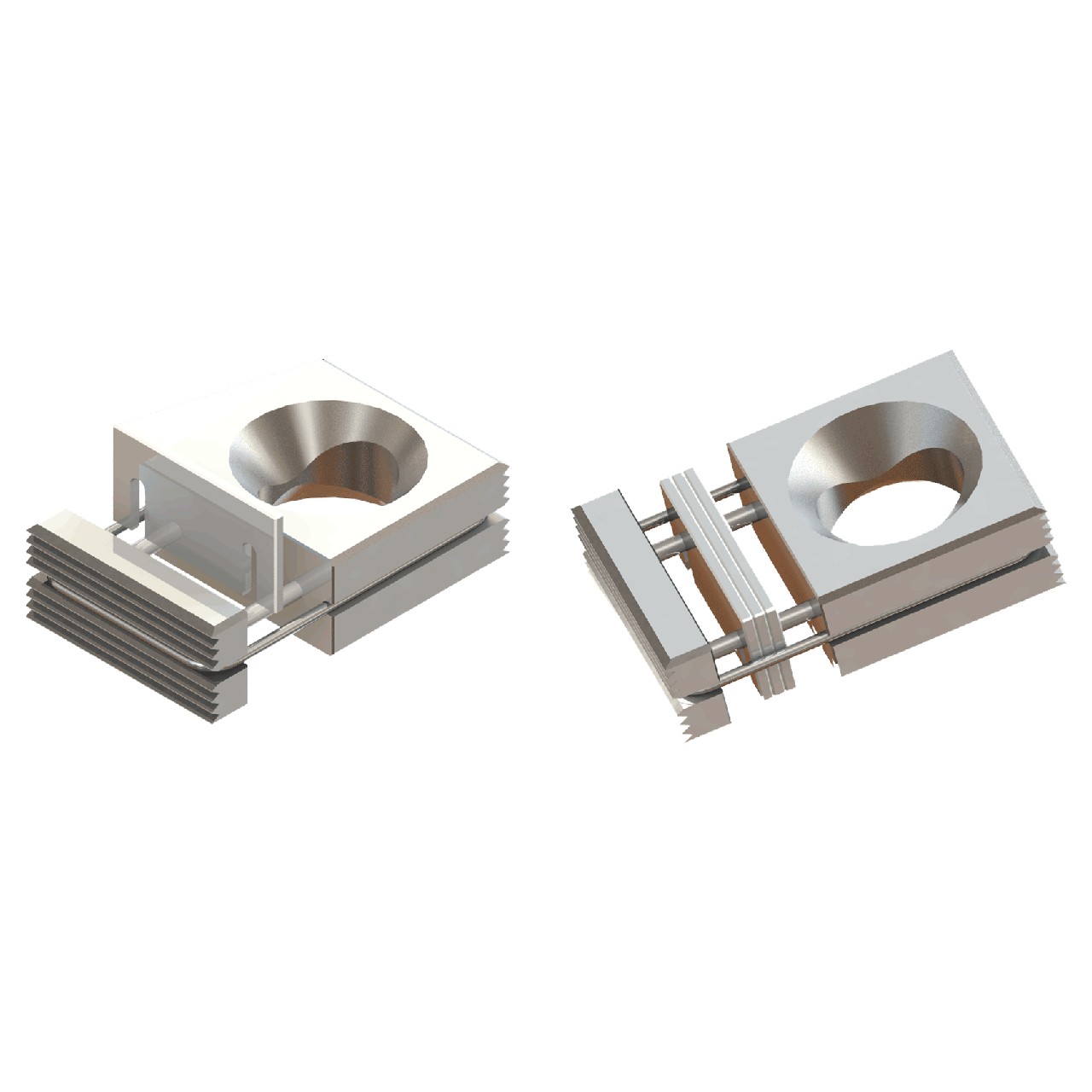

Modular Jaw

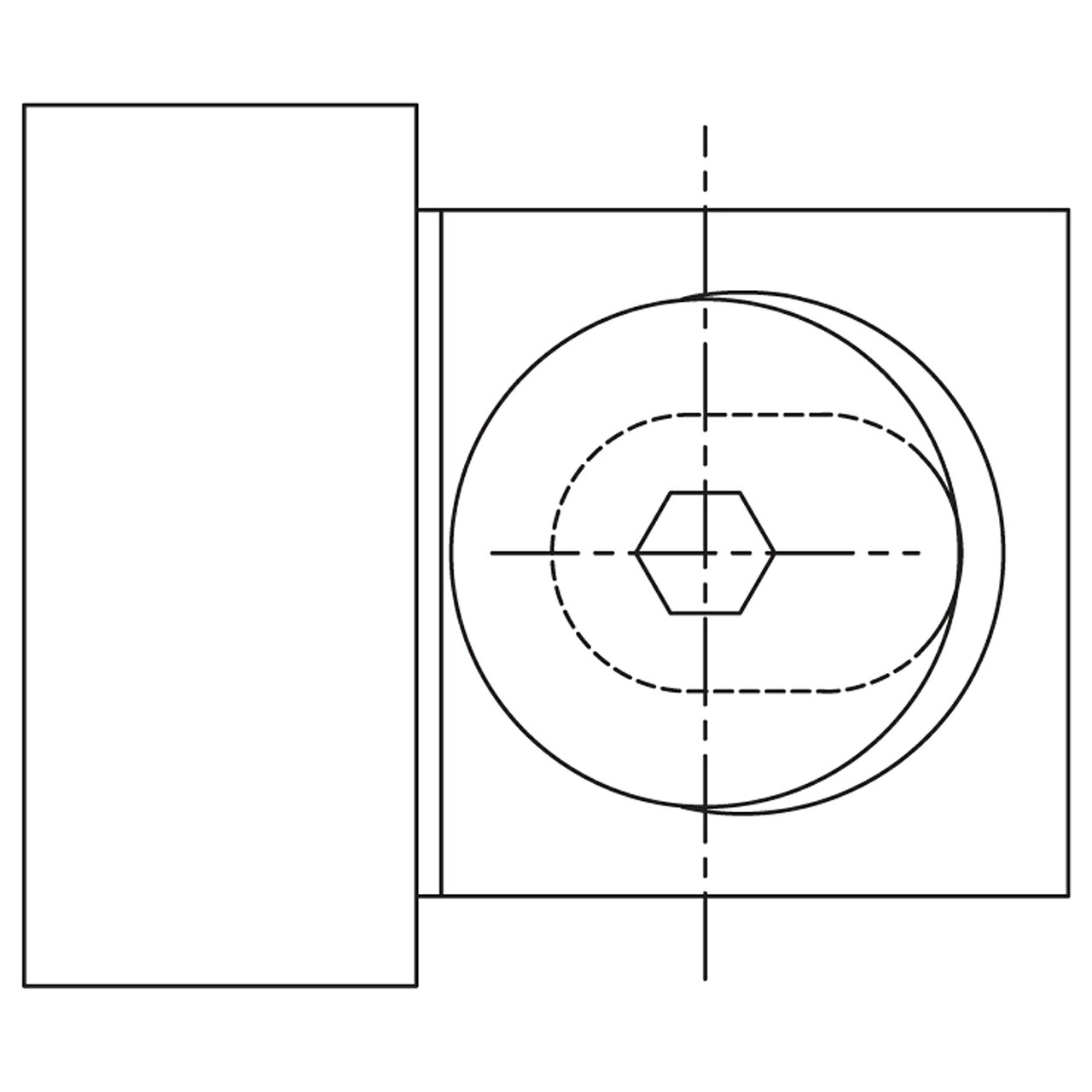

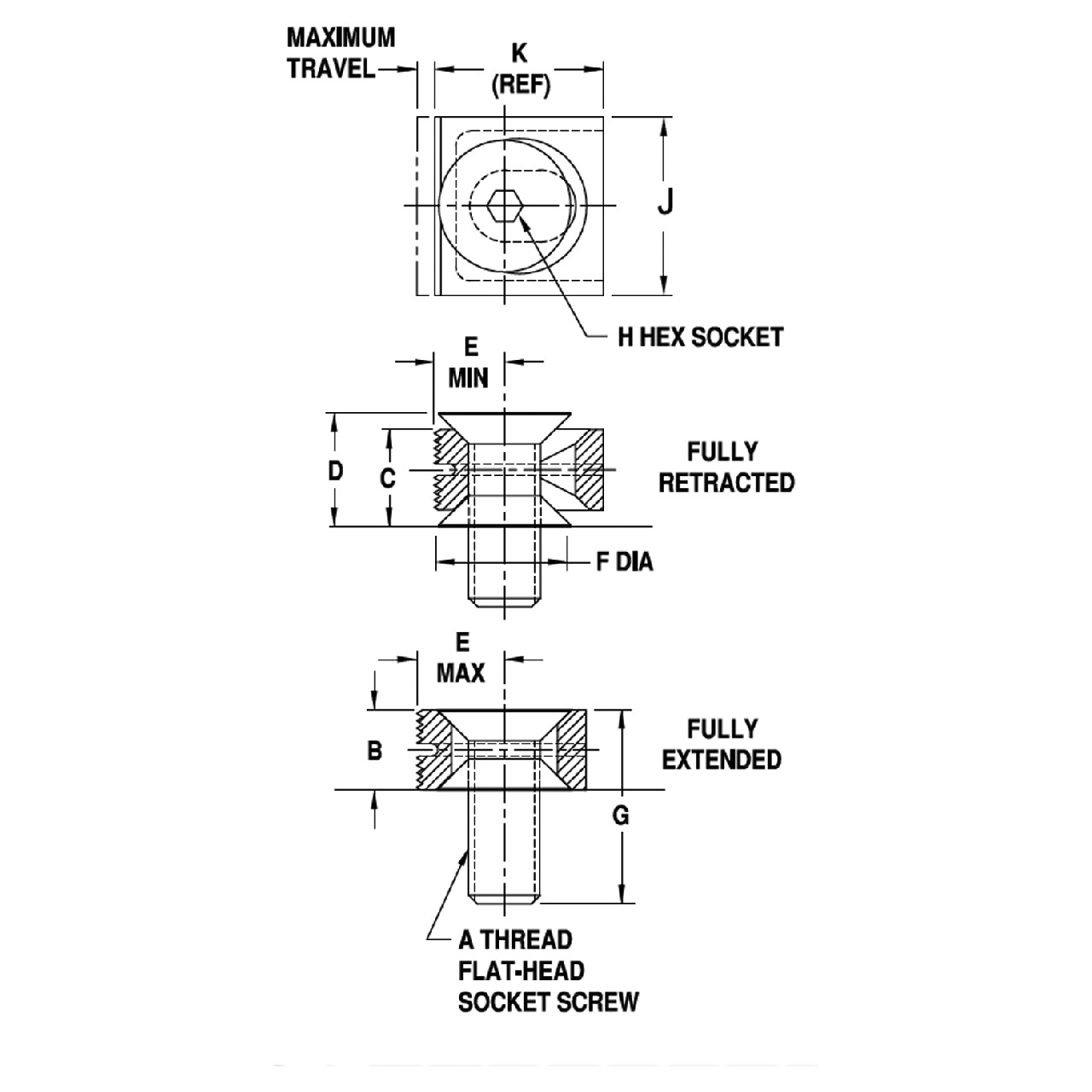

Tiny Vise M-series incorporates a modular jaw design for greater adjustability. This new modular system allows adjusting the workpiece engagement point by adding or removing spacers. This is useful when using the same fixture for machining a family of parts, or when workpiece size can vary somewhat between batches. This version is available in two sizes, with 5/16-18 and 1/2-13 threads, and can be set up to apply force either at a downward angle or straight horizontally. Just like original Tiny Vise, these mini edge clamps securely grip the side of a workpiece to keep the top clear for machining. The patented design features a slotted countersink to provide strong, reliable clamping force with the easy turn of a hex wrench. These compact clamps are ideal for fixturing multiple parts, small or large. Made in USA.

Adjustability

Modular jaw design allows adjustment for workpiece-size variations.

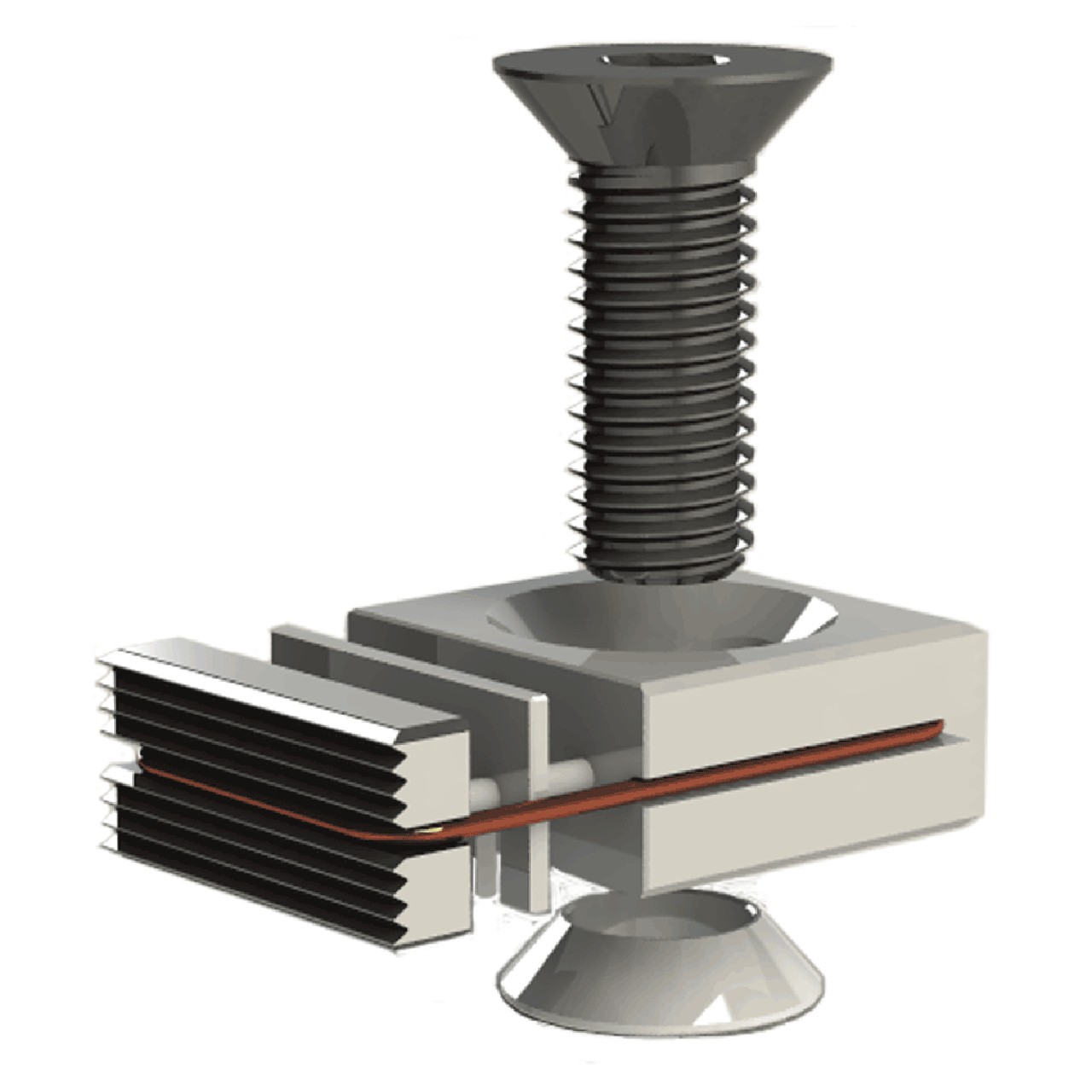

M-series clamps have a 1/4"-thick modular jaw that can be easily extended to insert or remove spacers. Up to three 1/16" spacers can be inserted to provide adjustment.

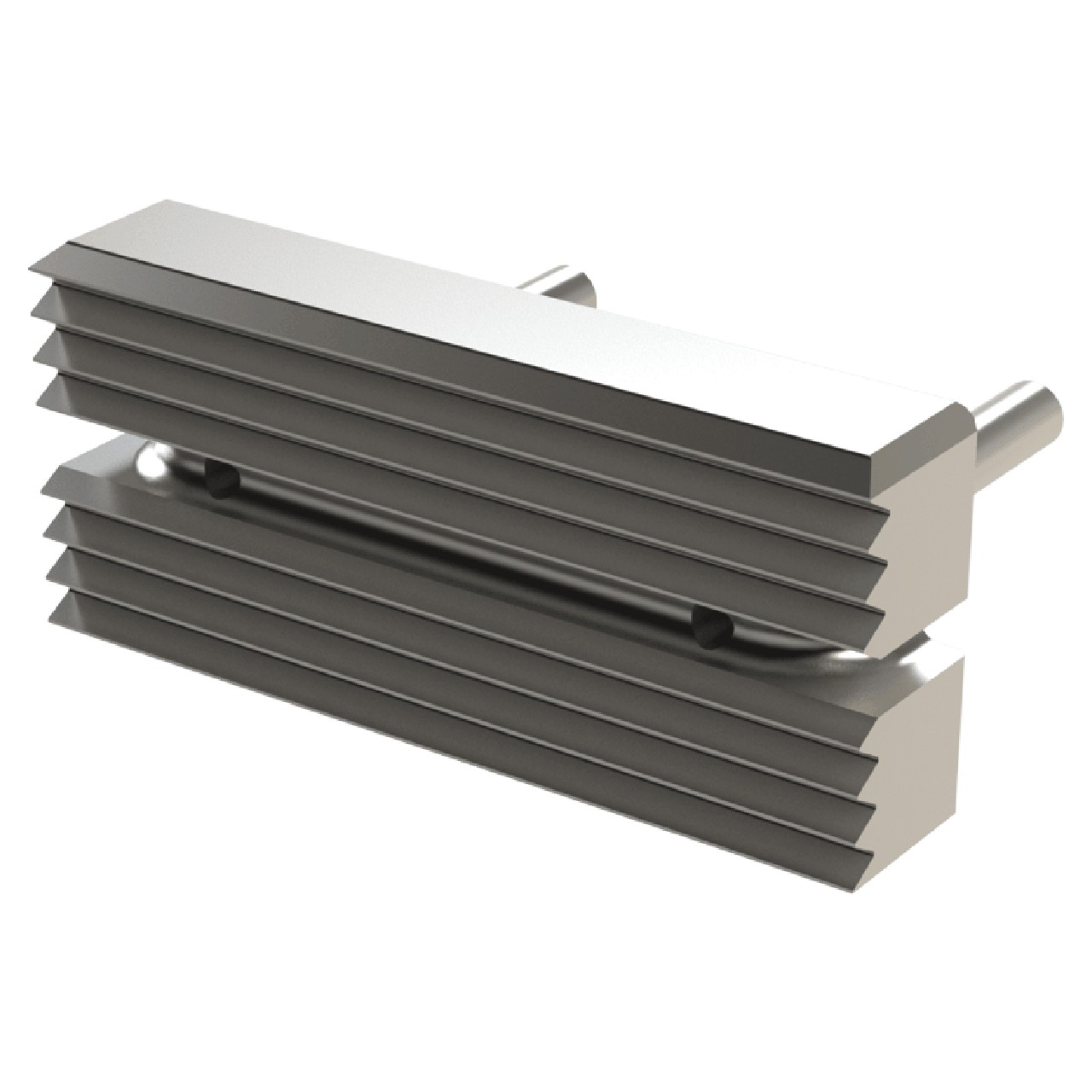

The M-series clamp body, without a jaw, is the same size as a standard Tiny Vise -- with the same reversible jaw faces (one serrated and one smooth), The 1/4"-thick serrated modular jaw mounts into the smooth face, and each spacer adds another 1/16". Up to three spacers can be inserted to provide adjustment. The modular jaw assembly is held together securely by a tough, durable O-ring, recessed in a protective groove. The modular jaw can be easily extended to insert or remove the slotted spacers.

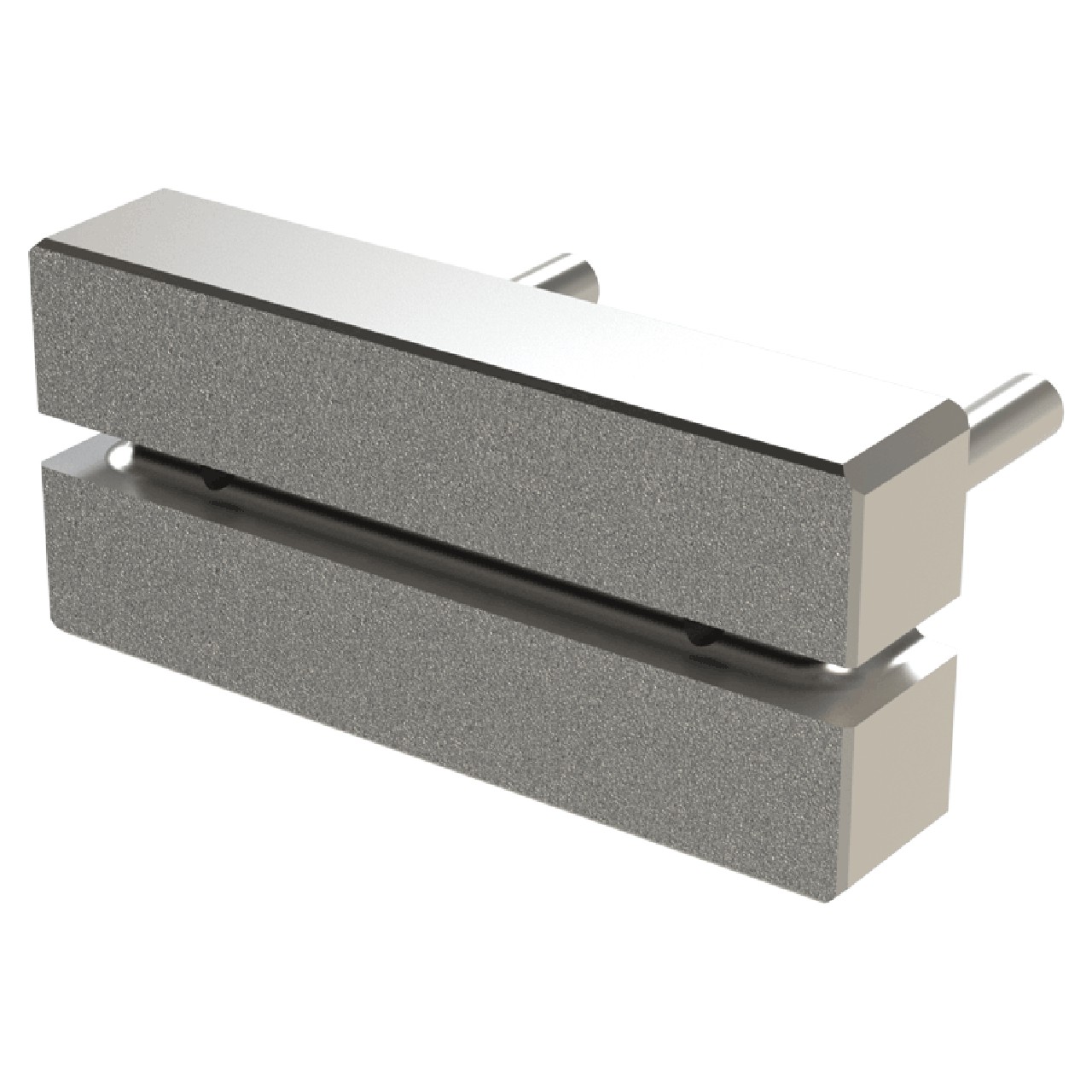

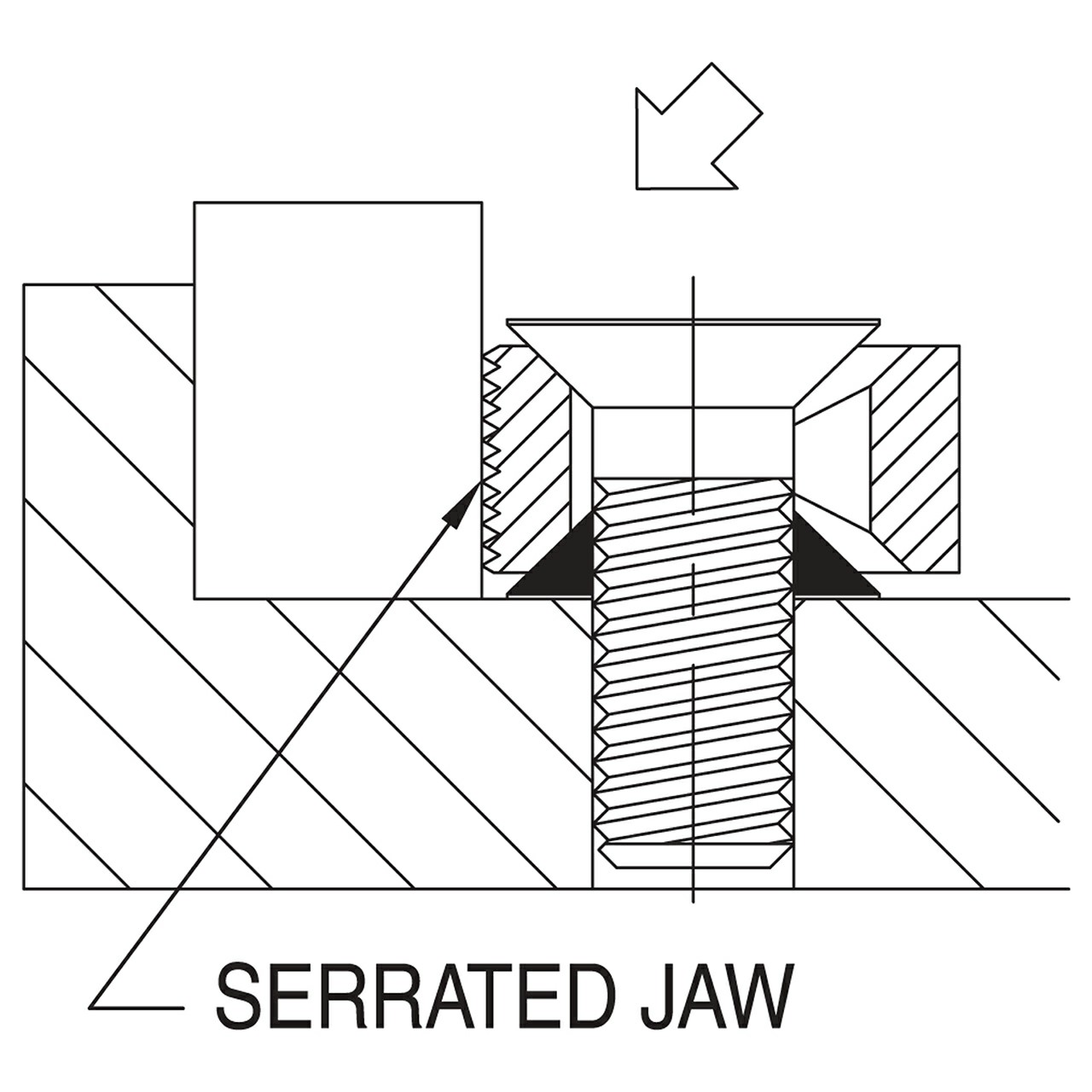

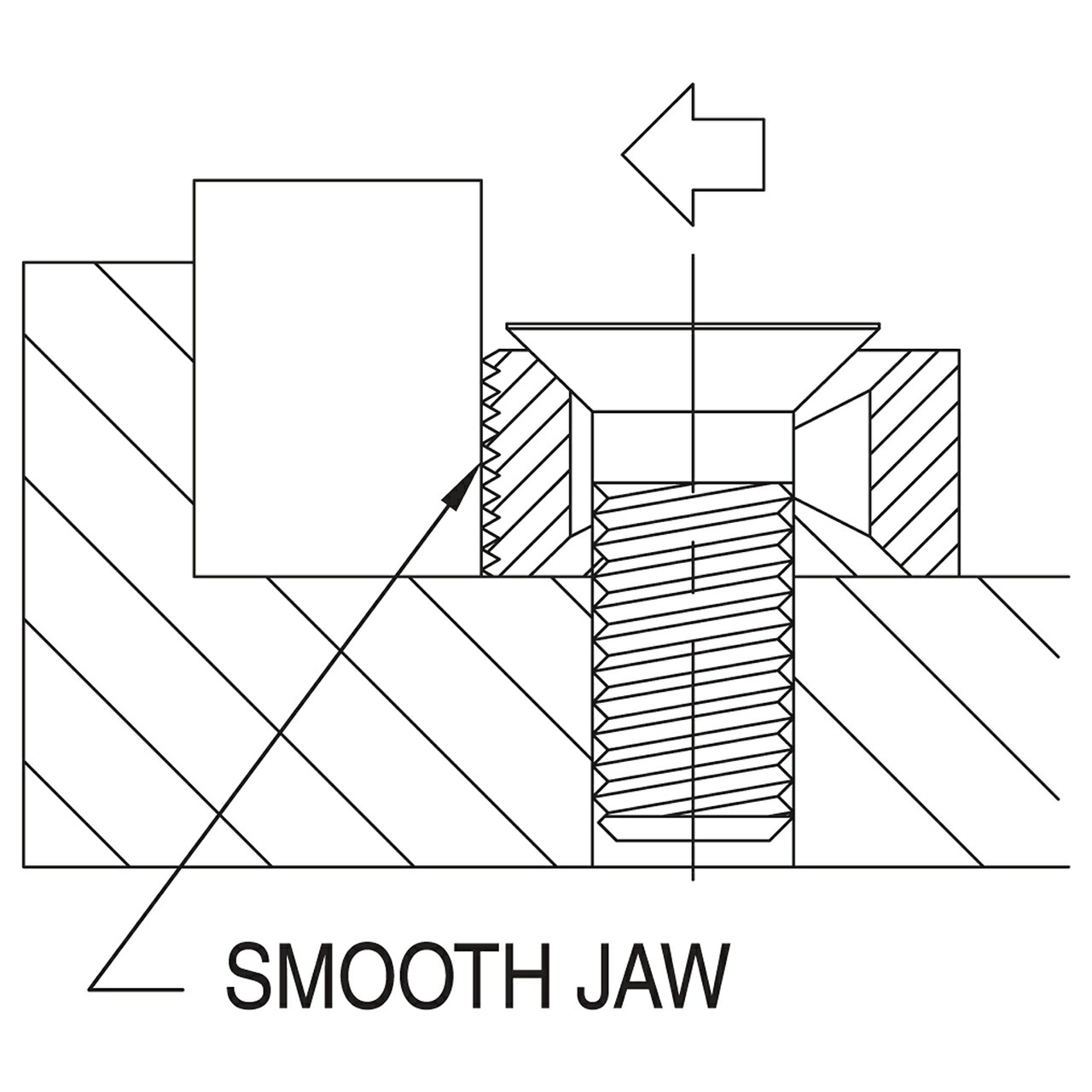

Choice of Jaw Faces

1) Serrated hardened steel, for maximum gripping bite

2) Smooth hardened steel, to avoid marirng on Finished surfaces

3) Smooth Delrin, to further protect Finished surfaces when less clamping force is required

4) Carbide-abrasive-coated steel, for strong gripping with minimal surface penetration

Choice of f modular jaw faces. Any of the f jaws can be mounted on the same body.

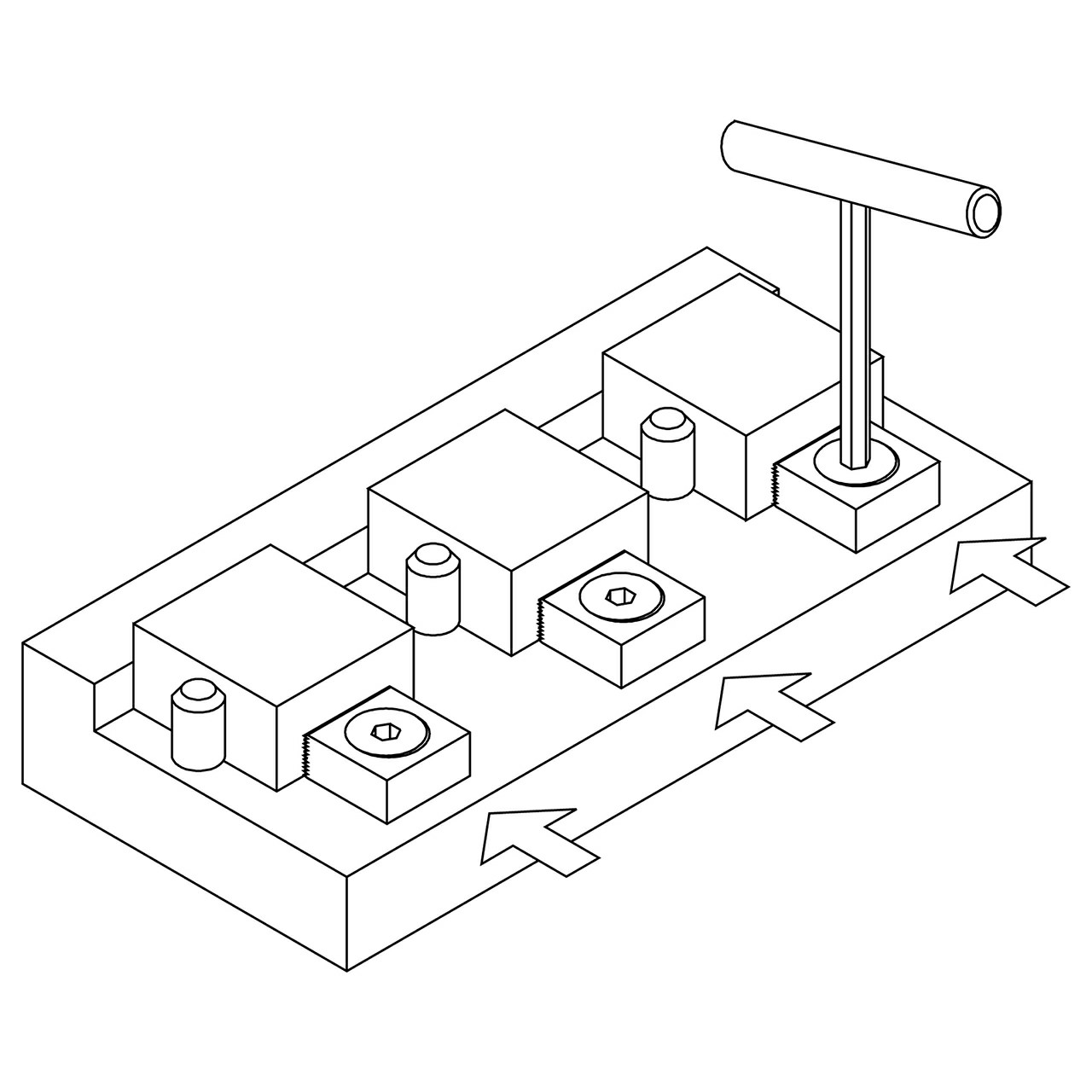

Clamping Action

Clamping force is applied by positive screw action with the easy turn of a hex wrench

Patented design features a slotted countersink

Clamping force is applied by positive screw action with the easy turn of a hex wrench (not with an unreliable, unsafe eccentric cam as used in other designs). A high-strength Flat-Head Socket Screw engages a mating slotted countersink to exert strong clamping force. Much more durable than other designs.

Optional Downthrust Force

Setup for Horizontal Force (without Bottom Thrust Washer)

Setup for Horizontal Force (without Bottom Thrust Washer)

Clamps can be set up to apply force either at a downward angle or straight horizontally. All clamps are supplied with an optional bottom thrust washer. Installing this washer under the clamp will raise the clamp slightly and provide downthrust force during clamping. If no downthrust force is required, install the clamp without the bottom thrust washer. Doing so will improve clamping speed because fewer screw turns are required.

Design Considerations

Tiny Vise clamps are designed to provide strong clamping force when tightened by hand. Do not exceed the recommended tightening torque. Recommended torque and clamping force are at 1/3 of yield strength, leaving 2/3 of holding capacity to resist external cutting forces.

Material

| Item | Material | Heat Treat | Finish | DFARS | RoHS |

| Body | 1018 Steel | Carburized Hardened | Black Oxide | Yes | Yes |

| Jaw | 1018 Steel | Carburized-Hardened | Black Oxide(or Delrin) | Yes | Yes |

| Thrust Washer | 1144 Steel | Heat Treated | Black Oxide | Yes | Yes |

| Flat-Head Socket Screw | Steel | - | Black Oxide | Yes | Yes |

Parts Specification

| Clamp Screw Size | Jaw Type |

| 1/2-13 | Carb |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

844.548.0100

844.548.0100

Quotes

Quotes

Quick Order

Quick Order