The Importance of Machinists in Today's World

Mar 01, 2019

Machinists help create our world. Without them, the bolts, pistons, or other elements that make our machinery run wouldn't be possible. They use a wide variety of tools to achieve their aims -- from a lathe tool post to machinist blocks and CNC machines. Today, much of the work is done with computer-controlled or mechanically controlled machine tools that make up different parts, instruments, and tools out of wood, metal, or plastic. You might find a machinist in a machine shop, factory, or toolroom, depending on what they're working on and what their primary function is. There's always a need for machinists, and so most machinists are guaranteed work after their education is finished. We'll discuss the role of a machinist, some of the main items they work with, and what skill sets are most important for a machinist to have.

What Is a Machinist?

At the most basic level, a machinist is someone who sets up and operates hand tools like lathe tool posts, and machine tools to either build, fix, or revise something made of metal, plastics, or wood. Traditional machinists can operate these tools, take apart and repair machine tools when necessary, build new parts from scratch when necessary, and reassemble the tool and continue working with it.

More specialized machinists might be a tool and die maker, a mold maker, or a programmer or operator. Almost every machinist has the basic background knowledge, but might choose to specialize in a certain area. Working with a lathe tool post and other machine shop supplies is a given in the business and most machinists get their experience on the job, though they also usually do an apprenticeship or vocational school, or attend a community or technical college.

What Major Tools Do They Work With?

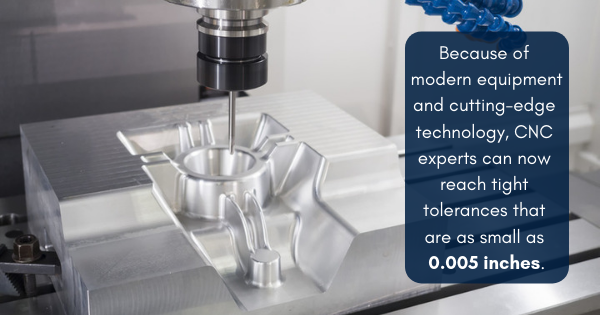

Production machinists will often use CNC machines -- computer numerically controlled machines. These follow a computer program that tells them when to change out tools, controls the speed, and performs all the necessary steps to create the part. The machinist is the person who figures out the cutting path, how fast the item is cut, and the feed rate; they often work with a computer control programmer to input all this information. A CNC machine has made a huge difference in what machinists can accomplish -- because of modern equipment and cutting-edge technology, CNC experts can now reach tight tolerances that are as small as 0.005 inches.

Lathes, lathe tool posts, milling machines, and grinders for tools may all be CNC machines, but these are common tools that a machinist will work with. It's important for machinists these days to be able to use both CNC machines and manual machines; some machinists may also learn basic programming to better operate CNC machines or troubleshoot if necessary.

They also need to know how to read computer-aided design (CAD) and computer-aided manufacturing (CAM) files, which might translate into the specific creation of a part later on in the process.

What Does a Machinist Need to Start Work?

Most machinist jobs require at least a high school diploma, though the majority of workers will also attend a vocational or technical college, or receive some kind of apprenticeship or specialized training. The technical or vocational college courses are usually about two years long and focus on design and blueprint reading, using different welding and cutting tools, and learning how to program and use CNC machines.

One common way is through long-term on-the-job training, which lasts 1 year or longer.

Trainees usually work 40 hours per week and take additional technical instruction during evenings. Trainees often begin as machine operators and gradually take on more difficult assignments. Machinists and tool and die makers must be experienced in using computers to work with CAD/CAM technology, CNC machine tools, and computerized measuring machines. Some machinists become tool and die makers.

Those who have graduated from these programs often will opt for an apprenticeship program, usually run by a manufacturer. They're paid for the work and receive other technical instruction, usually at night, for a few years.

Machinists are an integral part of the manufacturing industry and it's a steady field that provides consistent, needed work.

714.897.1700

714.897.1700

Chat

Chat

Email

Email

844.548.0100

844.548.0100

Quotes

Quotes

Quick Order

Quick Order