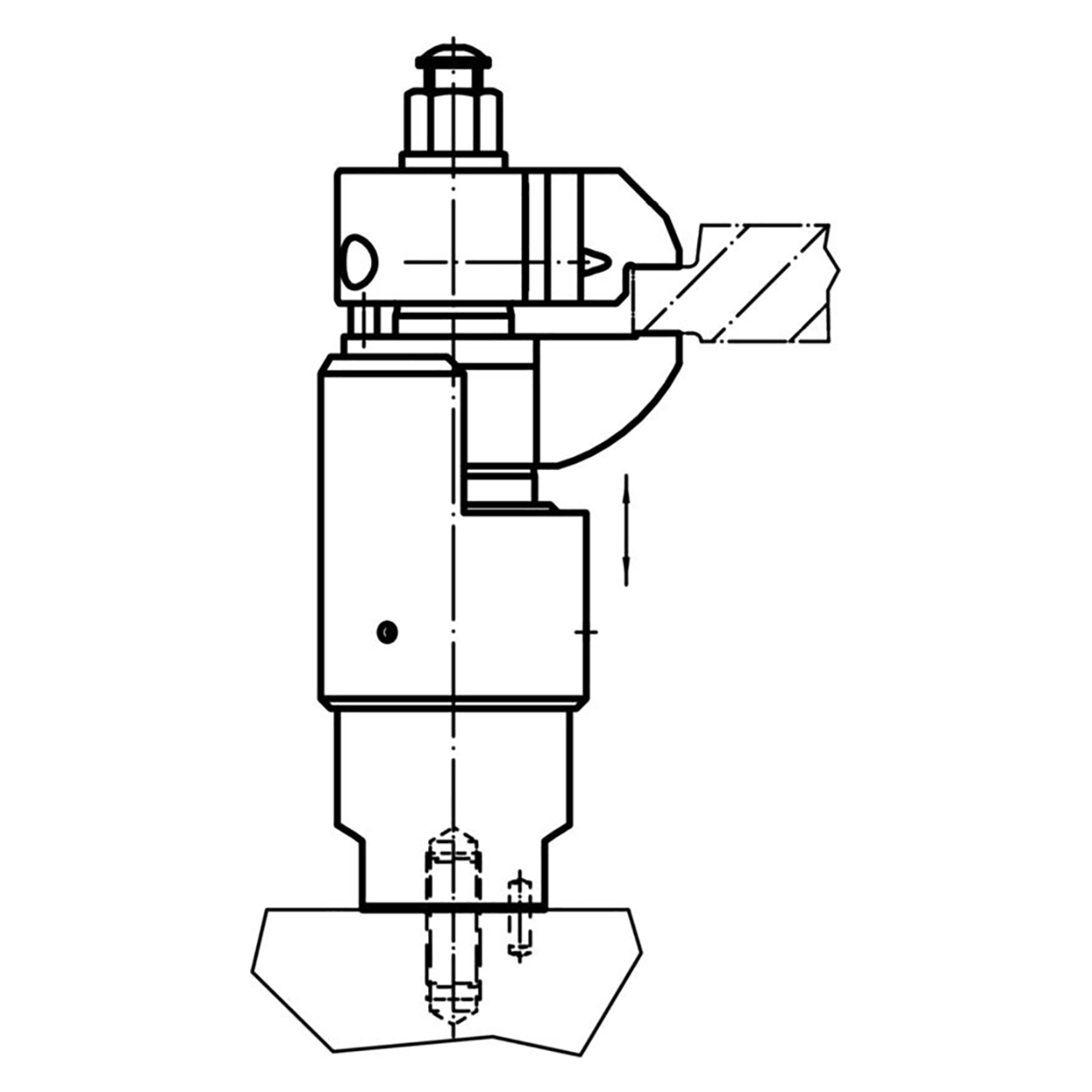

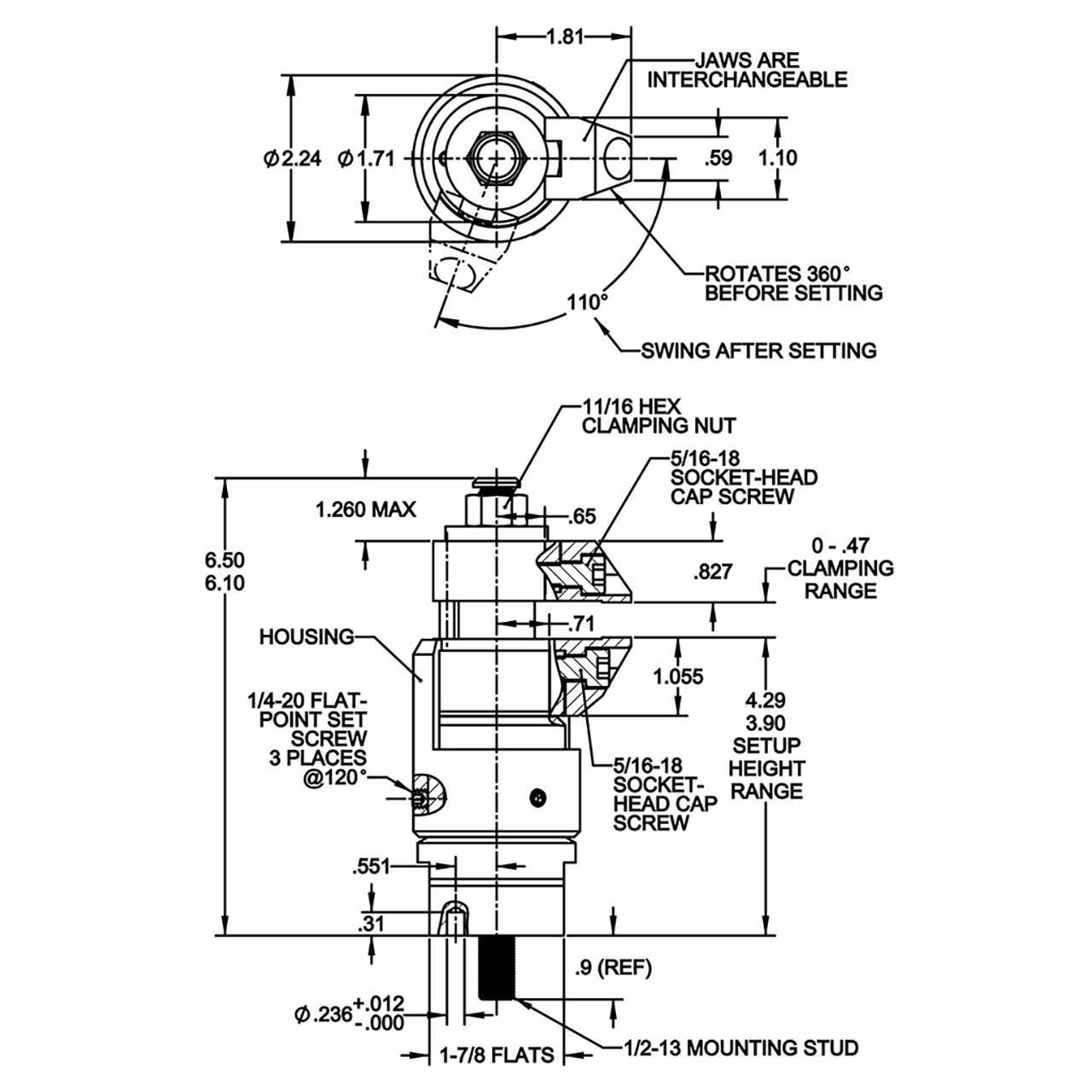

Floating Clamp

Floating Clamps are position-flexible clamping devices. The top jaw and bottom jaw together provide a floating clamping point that adjusts to the workpiece before locking, to prevent deformation. These combination clamp/supports are often used in conjunction with primary locators and clamps, providing additional support points to reduce machining vibration. Floating Clamps are especially useful for clamping forgings, ribbed or flanged castings, and other larger parts.To initiate clamping, push the Floating Clamp downward, then immediately swing the jaws into clamping position. The clamping jaws will automatically rise so that the bottom jaw contacts the workpiece with a light spring force. Next, tighten the top hex nut 11 ft-lbs minimum to 22 ft-lbs maximum, depending on the support load capacity desired.

Application Information

Setup & Operation

Setup: Install the clamp in a 1/2-13 threaded mounting hole by tightening using the body wrench flats. Adjust the height-limit stop and the swing range with the three setscrews in the green housing. When setting the height limit, consider the full range of workpiece tolerance.

Material

| Item | Material | Heat Treat | Finish |

| Housing | Aluminum | - | Anodized Green |

| Body | Steel | case hardened & nitrided | manganese phosphate treated and ground |

| Clamping Jaw | Steel | case hardened & nitrided | manganese phosphate treated |

Parts Specification

| Mounting Stud Thread | Support Load Capacity At Minimum Tightening Torque | Support Load Capacity At Maximum Tightening Torque |

| 1/2-13 | 450 lbs @ 11 ft-lbs | 1800 lbs @ 22 ft-lbs |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order