Product Information

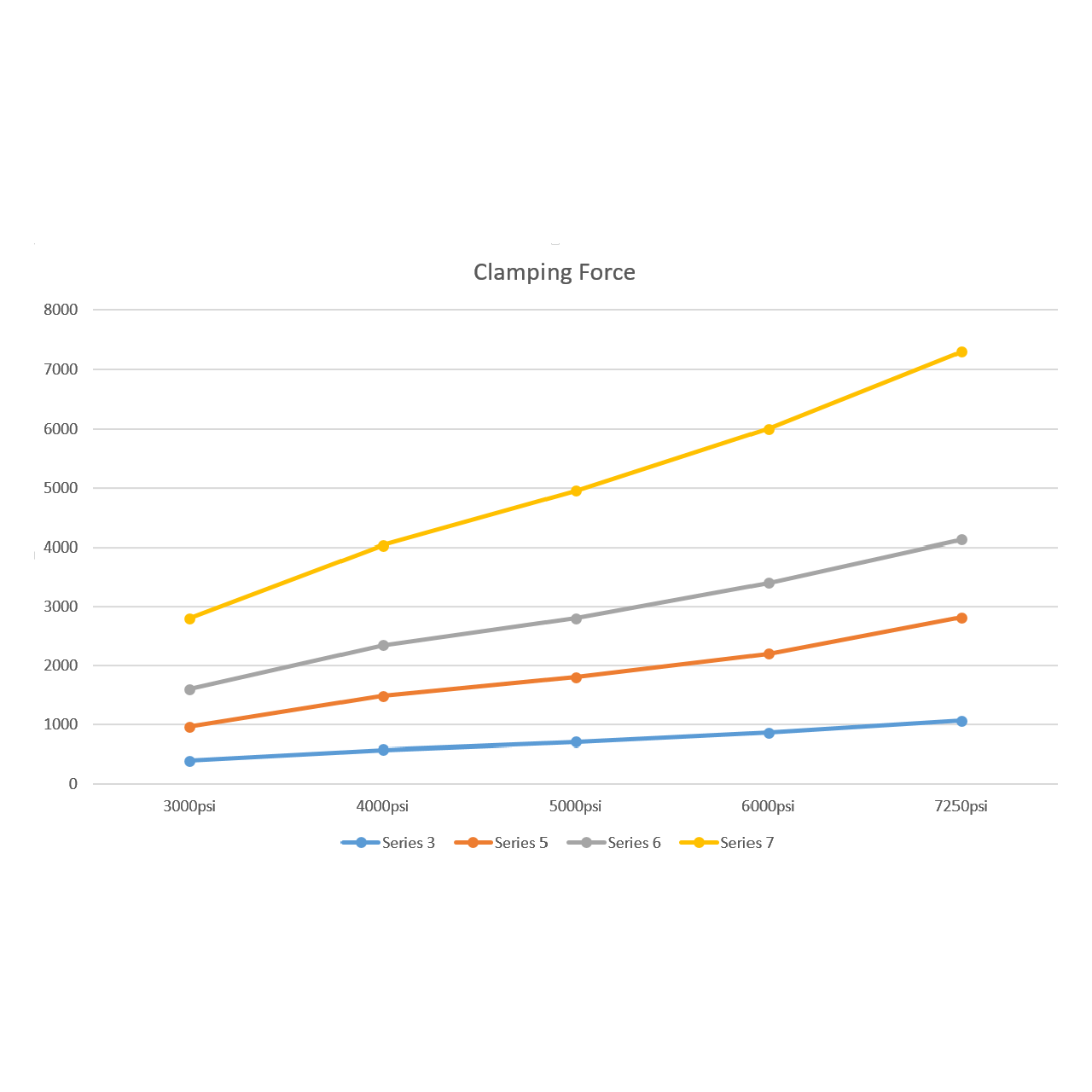

3000 to 7250 psi max Single and Double Acting Swing Clamps utilize a sturdy helical-cam mechanism to swing the clamping arm clear for unrestricted loading. The Standard Swing Clamps shown here accept a wide variety of clamping arms, with maximum allowable operating pressure depending on the type of arm selected (3000 to 7250 psi max). These Swing Clamps incorporate our unique safety-clutch mechanism. If the clamping arm strikes an unexpected object during its swing, the clutch disengages to avoid damaging the object or the clamp's helical-cam mechanism. Clamping arm can be mounted to start its 90 Degree swing from any position within 360 Degree. The top-flange version shown here allows low-profile installation. Dual mounting capability provides every clamp with the option of using either standard fittings or manifold mounting. Available in four clamp sizes, single or double acting, with a choice of clockwise, counterclockwise, or zero Degree swing. Available with 45 Degree and 60 Degree swing angles by special order. Double-acting clamps are also available with longer clamping strokes (25mm or 50mm) by special order. Clamping force at 7250 psi for single-acting clamps with a pivoting clamping arm: 1060 Lbs (3 series) 2700 Lbs (5 series) 4200 Lbs (6 series) 7300 Lbs (7 series)

Application Information

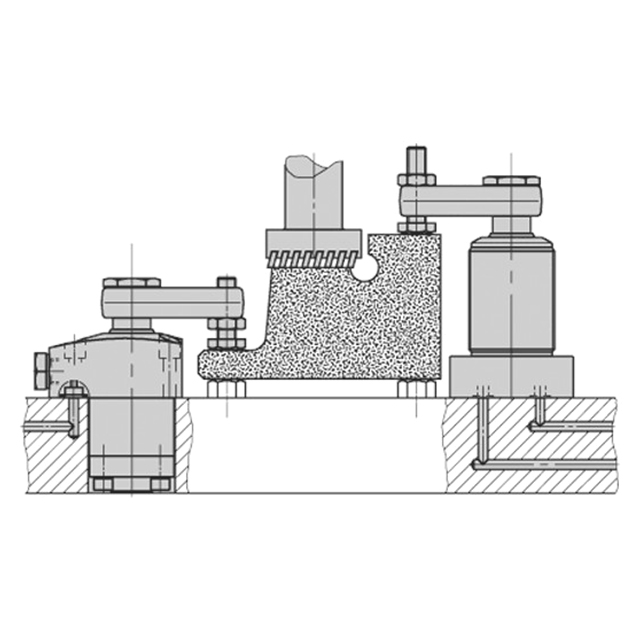

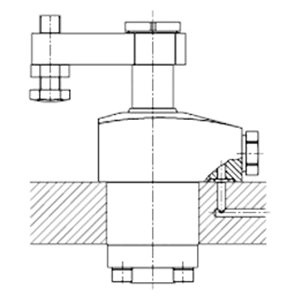

Top-flange swing clamp used together with a flange-base swing clamp to clamp at different heights. Both clamps are manifold mounted, with fluid passages in the base plate.

Sizes & Clamping Force

Clamping force with Pivoting Arm

Clamping Action

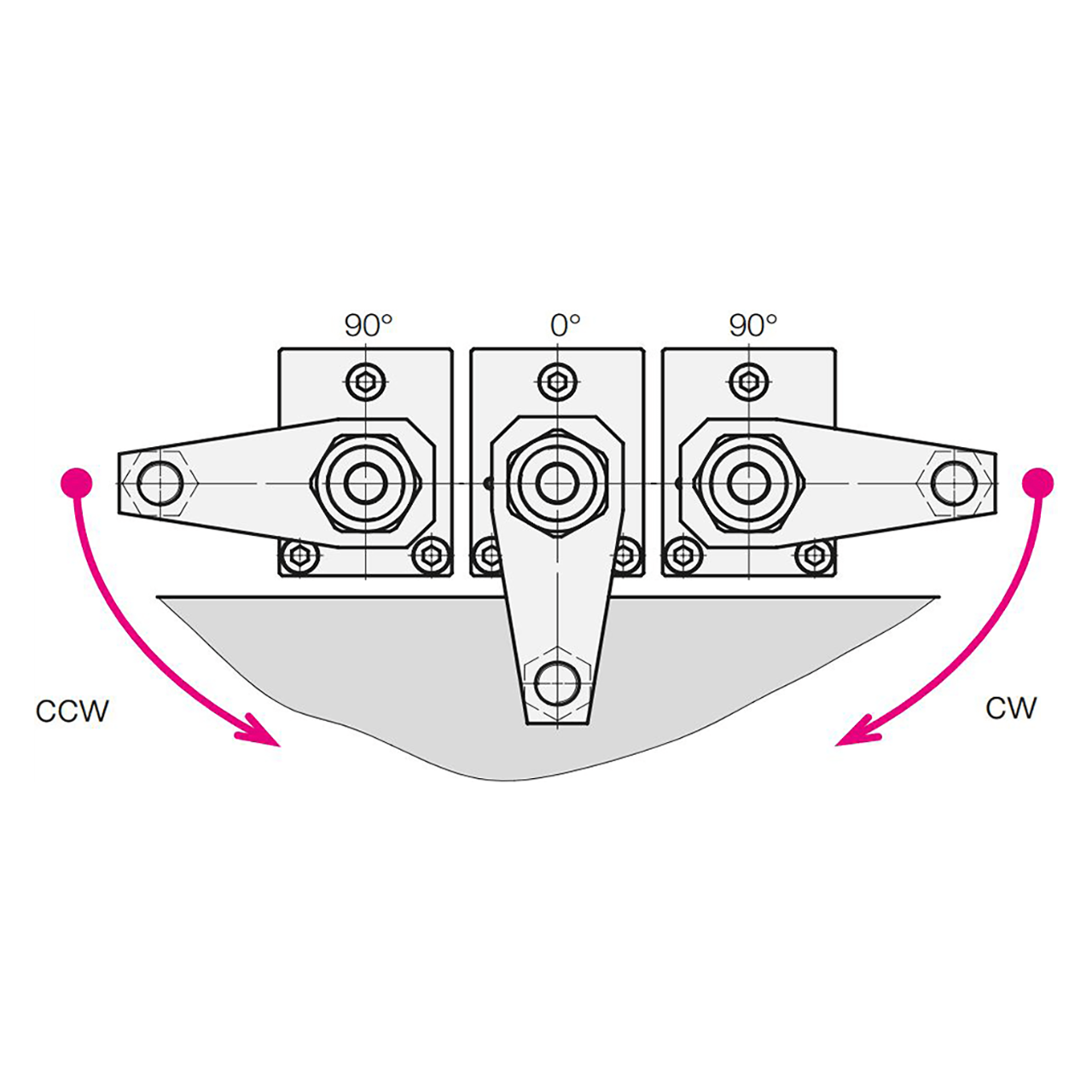

Available with clockwise, counterclockwise, or zero Degree swing Swing Clamps are pull-type cylinders where part of the total stroke is used to swing the piston, and the remaining stroke is available as the clamping range. Applying fluid pressure swings arm 90 Degree over workpiece then clamps down. Single-acting version has a fast, totally dependable spring return that lifts arm then swings it back 90 Degree for loading/unloading. Optional fluid return (double acting).

Design Considerations

These Swing Clamps incorporate our unique safety-clutch mechanism. If the clamping arm strikes an unexpected object during its swing, the clutch disengages to avoid damaging the object or the clamp's helical-cam mechanism. Do not exceed maximum fluid flow rate in table. For extended clamp life and proper operation of the safety clutch, a simple flow-control valve may be required if the fixture is powered by a high-flow-rate power source and only contains a few clamps. Clamping time should be at least one second.

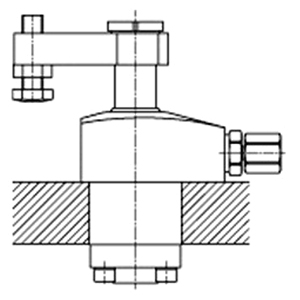

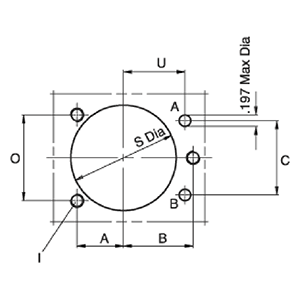

Mounting & Fluid Supply

Standard Fittings Manifold Mounting Fasten clamp with three socket-head cap screws. Dual mounting capability provides every clamp with the option of using either standard fittings or manifold mounting. 1/4" BSPP port (two for double-acting clamps). Do not use NPT fittings. For optional manifold mounting, use the O-ring port underneath, instead of the standard port (two for double-acting clamps). For manifold mounting, the mounting surface must be ground flat to ensure proper O-ring sealing. Unscrew the sealing plug in each O-ring port and install a CLR-3000-347-SW O-ring (also install a CLR-810-F Port Plug in each 1/4" BSPP port).

Clamping Arm

Standard Clamping Arm3000 psi max Gooseneck Clamping Arm5000 psi max Pivoting Clamping Arm7250 psi max Order clamping arm separately. Maximum allowable operating pressure depends on the type of arm selected. Choose a Standard Clamping Arm for 3000 psi max, a Gooseneck Clamping Arm for 5000 psi max, or Pivoting Clamping Arm for 7250 psi max (requires a rear support). Longer, custom clamping arms will further reduce allowable operating pressure, inversely proportional to arm length.

Parts Specification

| Part Number | CLAMP SIZE | SWING DIRECTION | MAXIMUM CLAMPING FORCE (lbs) | MAXIMUM CLAMPING FORCE (kN) | LENGTH (mm) | WIDTH (mm) | HEIGHT (mm) | CLAMPING STROKE (mm) | TOTAL STROKE (mm) |

| CLR-1897-103 | 7 Series | 90 Degree cw | 7800 | 34.5 | 125 | 95 | 182 | 15 | 24 |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order