3 Ways to Maximize CNC Toolholder Longevity

Apr 12, 2019

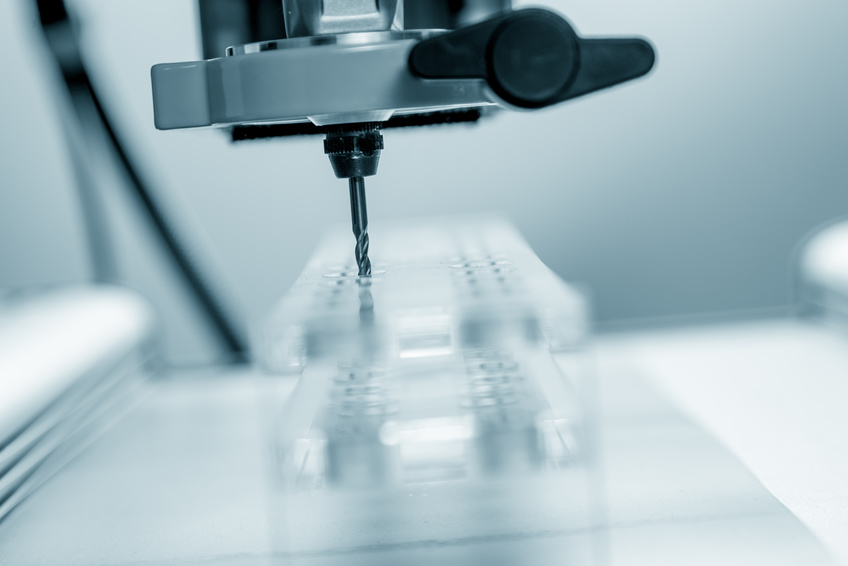

Computer numerical controlled (CNC) tools are highly sophisticated tools used in metalworking. They're able to use computer logic to control movement and are therefore able to perform the necessary metalwork. Because of this, CNC tools can produce complex parts that today's technology demands. As computers have become more advanced, CNC tools have become more widely used as laser cutters, lathe tools, jet cutters, and other types of industrial tools.

Toolholders are essential for any industrial tool company using CNC tools. As Merriam-Webster explains, these are short spindles having a shank at one end. The shank clamps to the machine and the clamp at the other end hold cutting bits that can be interchanged. American Machinist believes that since the various kinds of toolholders each have different reactions to cutting forces, it's extremely important to inspect parts at frequent intervals. Here are three examples of what to look out for.

1. Check for Side Load Wear.

This type of wear is common in end-mill toolholders due to the substantial side loads they're exposed to. As time passes, the inner diameter of end-mill toolholders begins to become bell-shaped. It's recommended that the toolholder be replaced when the wear becomes excessive.

2. Check for Cleanliness.

It's critical to routinely clean the mating parts of a machine. In the course of heating, oil can become sludge which acts as a glue holding the parts together. Using a non-flammable cleaning solvent to clean any mating parts resolves this issue.

In addition, if you're using rust protection fluid with a 3.3% concentration and it was inadequate in the fall and winter, you might need to increase the concentration to 4%, or to a point where rust isn't visible any longer.

3. Check Retention Knobs.

Retention knobs are crucial for holding the tool in a spindle. These parts must withstand substantial forces, including drawbar pull, tightening torque, or, in the case of end-milling, pull forces caused by the cutting action. For this reason, you should inspect retention knobs often and replace them every two years of normal use.

Just as a machinist must keep all pocket calipers, portable floor jacks, and all other machine shop supplies well-maintained, keeping CNC tools in proper working condition is a high priority for an industrial tool company. An essential part of that is making sure that all CNC toolholders are in good shape. By frequently checking your toolholders for signs of side load wear, cleaning machine parts frequently, and checking retention knobs, you'll ensure that your CNC toolholders are working well -- and you'll prolong their work life as well.

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order