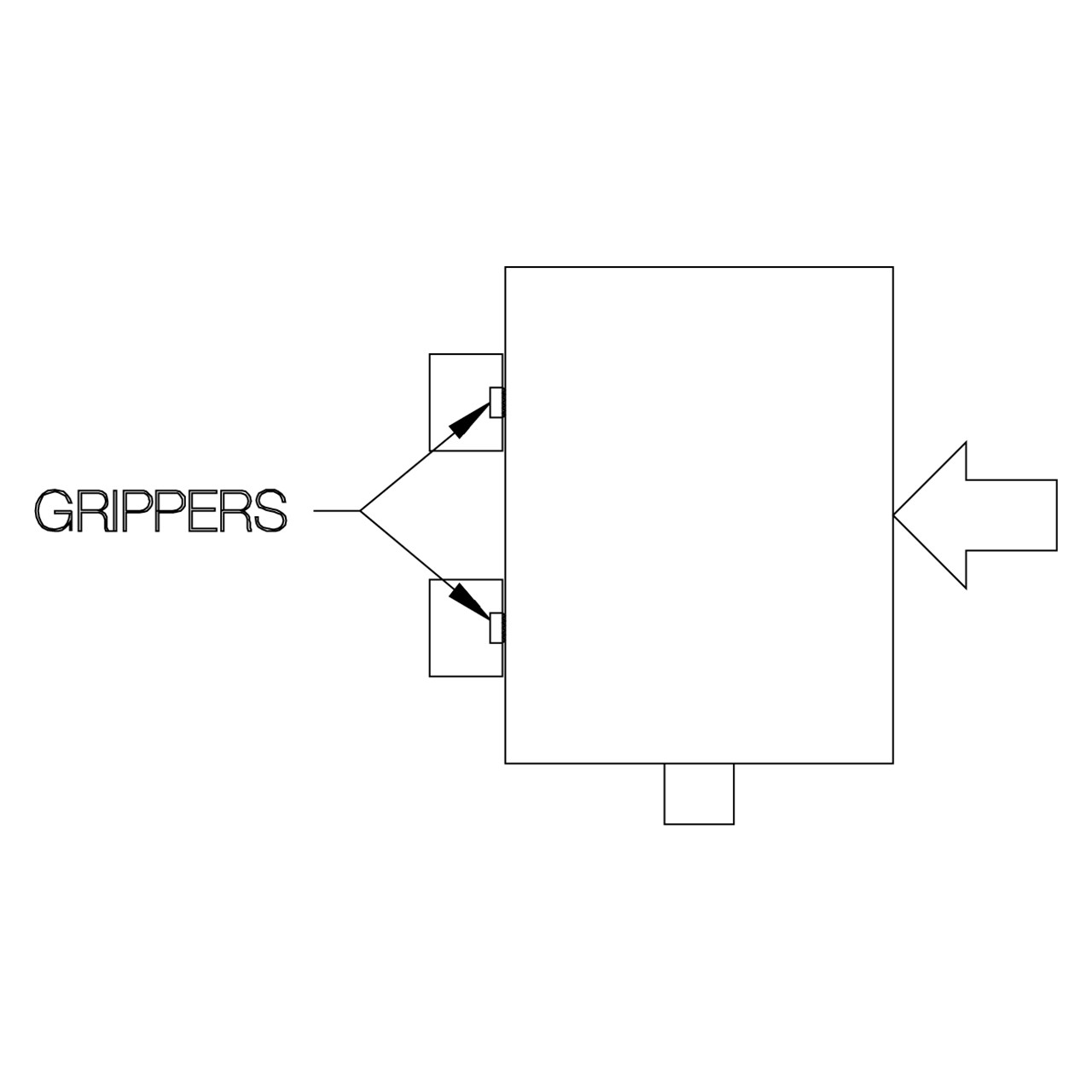

Round Grippers

Serrated are hard, replaceable inserts that provide additional holding force and/or wear resistance when installed in a fixture. These grippers are designed to slightly penetrate the workpiece to significantly increase gripping force, rather than relying on static friction alone. The hardened tool steel grippers are the most economical and impact resistant. Made in USA.

Application Information

Simple customized blank chuck jaws with serrated grippers installed can provide holding force comparable to fully serrated hard jaws.

Serrated grippers installed in a fixture's locating surfaces dramatically increase resistance to movement by embedding themselves in the workpiece.

Installation

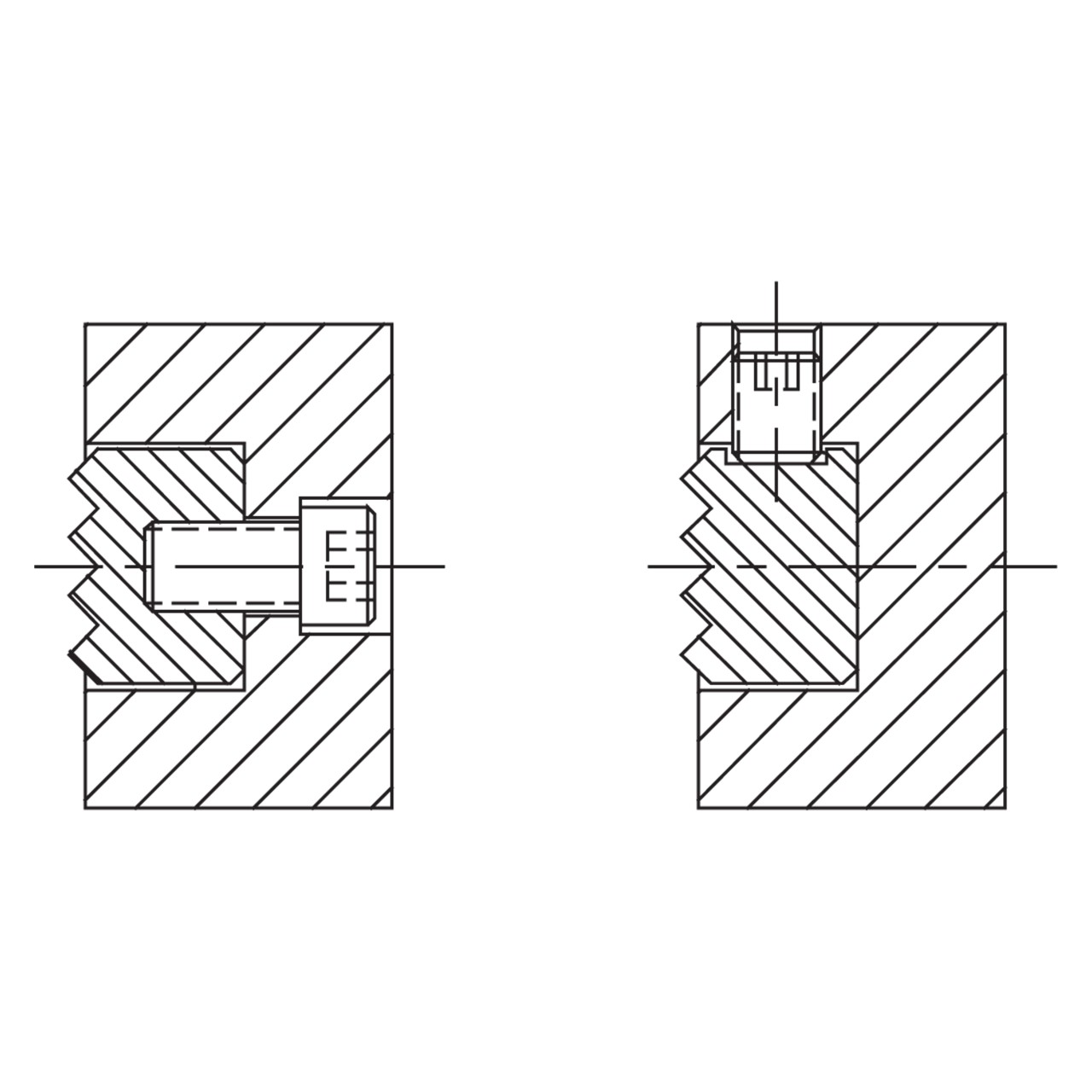

These tapped Round Grippers can be fastened from behind with a socket-head cap screw, or clamped with a setscrew on the O.D. locking flat (1/4"-diameter grippers do not have a locking flat). Grippers can be recess-mounted in a flat-bottom hole, or surface mounted to use as a rest pad. When grippers are installed in a hole, they should project 50 to 100% of serration height for maximum effectiveness (serration height is .047" on grippers with .094" x 90° serrations, .062" on grippers with .125" x 90° serrations). Tapped Round Grippers can also be installed in Gripper Swivel Pads and Gripper Swivel Contact Bolts.

Material

| Material | Heat Treat | Finish | DFARS | RoHS |

| M-2 tool steel | Heat Treated Rc 60-62 | Black Oxide | Yes | Yes |

Parts Specification

| A Diameter (mm) | B (mm) | C Thread | Thread Pitch (mm) | D (mm) | E (mm) | F (mm) | Serrations | Serration Dimensions |

| 20mm | 10mm | M6 | 1mm | 5mm | 4.7mm | 4.5mm | Fine | 3.2x90° |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order