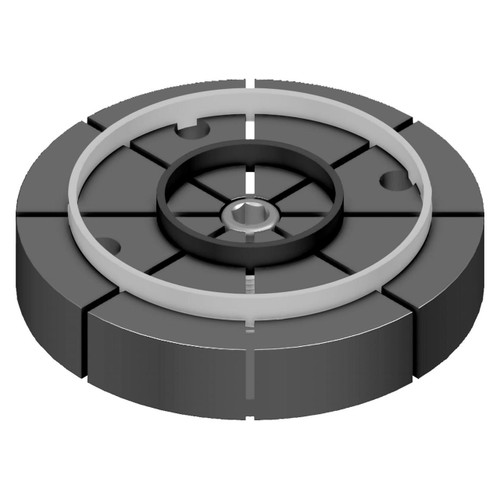

The ID Xpansion clamp is the ideal solution to hold parts on an inside diameter for high density machining on vertical or horizontal machining centers. It can also be used as an expanding mandrel on a lathe.

These machinable clamps are produced in 12L14 steel with black oxide coating in 12 sizes and can hold internal diameters from under 3/16 to almost 10 inches (4.1 to 254 mm). #10 manufactured using 7075-T6 aluminum.

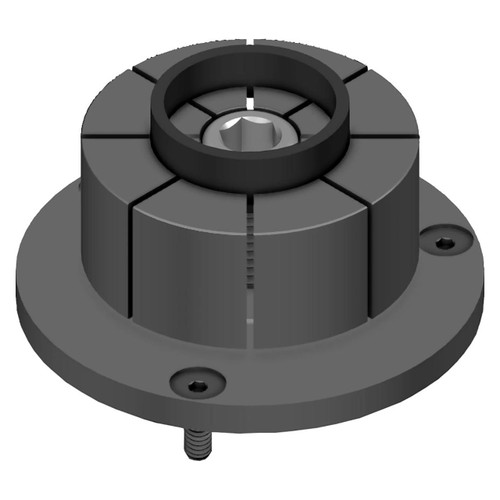

The flange diameter of the clamp is held to a close tolerance for precision locating in a machined pocket on work cubes and fixture plates.

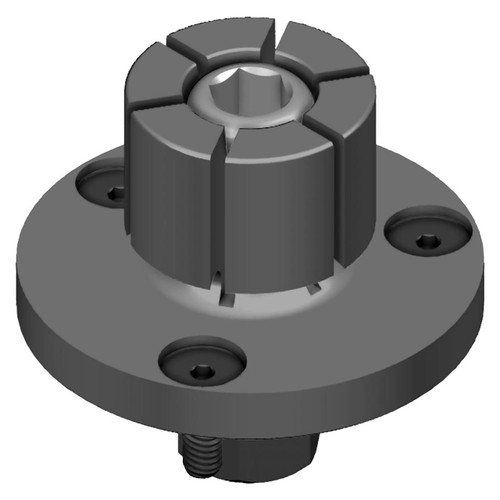

The customer machines the mild steel clamp to match the bore of the part ensuring a proper fit. Often times the clamps can be remachined for different size jobs.

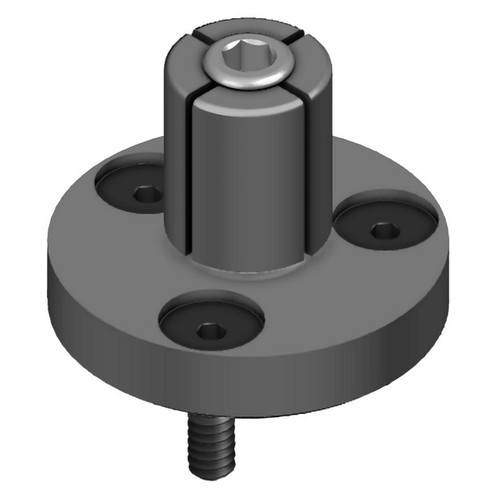

The low profile ID Xpansion Clamp can hold several parts in one compact area for secondary operations without any clamping interference. They are quickly tightened with a hex key, torque driver or can be mated to hydraulic pull cylinders for automation.

Features:

- Low Profile

- Ideal for Secondary Operations on lathe parts

- Easily machined to size on lathe or mill

- Excellent for palletized setups

- Allows more parts per workcube or fixture plate

- Heat-treated and coated screw for long life

- Clamp body made of mild steel for machinability

- Tighten with hex key or hydraulic pull cylinders(Drill clearance hole for longer bolt into cylinder)

- Longer screws available for hydraulic applications

- Longer tapered screws available for each ID size

- Tungsten Carbide coating can be added to increase holding force

| Screw Size | 5/8-11 |

| Maximum Torque | 125 ft/lb |

| Holding Force | 6000 lbs |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order