Description

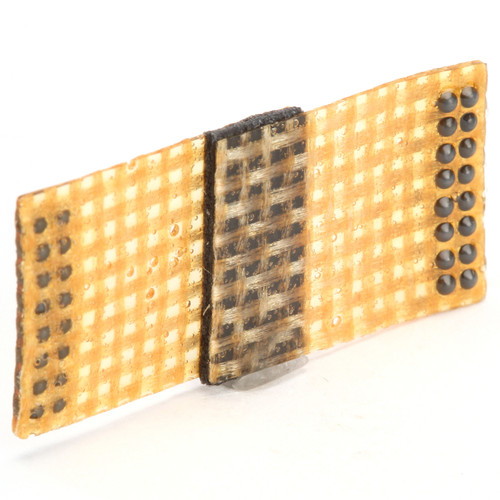

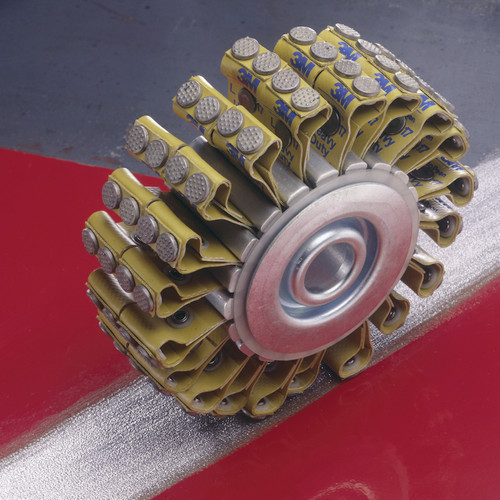

The 3M 7000000788 Roto Peen Flap Assembly delivers a portable, precise peening tool for a wide array of metals. Made with captive shot flap technology, this tungsten carbide peening tool bonds TC-330 shot to flexible flaps for uniform, efficient performance. Unlike traditional shot blasting, its integrated flap design ensures clean operation without loose debris. Compact assembly size allows for easy access to small areas, holes, and complex radii, making it ideal for in-service rework and manufacturing tasks. The assembly’s high strength resin and adhesive maintain consistent shot distribution, imparting compressive residual stress to enhance material fatigue resistance. Operators achieve controlled peening intensity through adjustable flap rotation speed and motion, ensuring uniform surface strengthening.

Product Features and Benefits

Portable Shot Peening Alternative

The portable flap / mandrel assembly serves as a shot peening alternative, eliminating the need for bulky sandblasting setups. Its compact design ensures access to tight or hard to reach areas without loose abrasives.

Clean and Precise Peening

The tungsten carbide peening tool’s captive shot flaps eliminate loose debris for a cleaner workflow. Precision bonding of TC 330 shot delivers uniform surface coverage and controlled peening intensity.

Enhanced Material Durability

By imparting compressive residual stress, the 3M Roto Peen Flap Assembly significantly improves fatigue resistance and crack prevention. This surface strengthening tool for metals extends component lifespan under cyclic loads.

Easy Intensity Control

Operators can adjust peening intensity through flap rotation speed and oscillation patterns. Consistent speed control ensures repeatable results across varying surface geometries.

Product Specifications

| Manufacturer Part Number | 7000000788 |

| Legacy SKU | 61986510594 |

| Overall Length (Inch) | 1.0" |

| Overall Length (mm) | 25.4mm |

| Overall Width (Inch) | 0.56" |

| Overall Width (mm) | 14.224mm |

| Application | Descaling, Heavy Duty Steel Cleaning, Coating Removal, Concrete Cleaning |

| Color Family | Yellow |

| Formula | Goldenrod |

| Product Form | Roto Peen |

Frequently Asked Questions

What is a captive shot flap assembly?

A captive shot flap assembly is a flap/mandrel system in which tungsten carbide shots are bonded to flexible flaps for debris-free peening.

How does the Roto Peen Flap Assembly function as a surface strengthening tool for metals?

It imparts compressive residual stress via uniform shot impact to improve material toughness.

Is the 3M Roto Peen Flap Assembly suitable as a precision peening tool?

Yes, its flap design and rotation control enable accurate peening on small or complex surfaces.

Why is this Roto Peen Flap Assembly considered a portable shot peening alternative and fatigue resistance metal treatment tool?

Its self contained flap design offers on site peening that boosts fatigue life without loose abrasives.

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order