Description

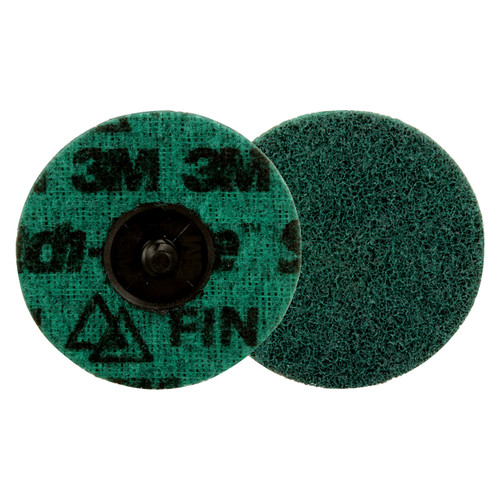

The 3M 7100264196 Roloc surface conditioning disc is a 3.0" PN-DR medium-grade disc made for controlled metal finishing. The disc employs precision-shaped ceramic abrasive to deliver consistent cut and finish balance for blending and refining. Its Roloc quick-change attachment provides fast, secure mounting to reduce downtime during tool changes. The medium grade is formulated to perform across finishing, deburring, radiusing and cleaning tasks on nickel alloys and similar substrates. The disc is designed for high-speed compatibility with disc sanders and right-angle grinders rated to the product's maximum RPM. Non-woven backing improves conformability and resists loading for a longer effective service life. Precision-shaped grains maintain cutting geometry and reduce glazing compared to conventional abrasives. The compact 3" diameter is ideal for localized blending, edge work and finishing in confined areas. Operators benefit from predictable abrasive action that reduces rework and improves finish uniformity. The PN-DR medium Roloc disc integrates readily into existing Scotch-Brite Roloc workflows and quick-change systems. Its construction promotes cooler operation and controlled stock removal during intermittent use. The product supports production and repair environments where consistent surface quality is required. Color-coded red helps operators quickly identify medium-grade discs on the work floor. The 3M 7100264196 disc is a dependable solution for industrial metal finishing teams seeking repeatable results. Follow recommended safety and mounting instructions when installing on compatible equipment.

Product Features and Benefits

Precision-Shaped Ceramic Abrasive

Maintains a consistent cutting geometry for extended life and predictable finishes on hard-to-machine alloys.

Roloc Quick-Change Attachment

The Scotch brite roloc surface conditioning disc facilitates rapid, tool-free disc replacement to minimize downtime and simplify inventory handling.

Medium-Grade Performance

Provides a balanced level of aggression suitable for finishing and blending without excessive material removal.

Non-Woven Backing

Delivers conformability to contours while resisting loading, preserving abrasive exposure during use.

High-Speed Compatibility

This Industrial metal finishing disc is designed for reliable operation on disc sanders and right-angle grinders within the product's rated RPM range.

Product Specifications

| Manufacturer Part Number | 7100264196 |

| Legacy SKU | 61500406881 |

| Backing Thickness (Inch) | 0.0 NP |

| Center Hole Diameter (Inch) | 0.0 NP |

| Center Hole Diameter (mm) | 0.0 NP |

| Center Hole Thread Size | Non Pertinent |

| Maximum Speed | 20000.0 RPM |

| Overall Diameter (Inch) | 3.0" |

| Overall Diameter (mm) | 76.2mm |

| Number of Vacuum Holes | -12345.0 |

| Number of Plies | -12345.0 |

| Product Type | Precision Surface Conditioning Disc |

| Abrasive Material | Precision Shaped Ceramic |

| Attachment Type | TR |

| Backing Material | Non Pertinent |

| Backing Weight | Non Pertinent |

| Color Family | Red |

| Grade | Medium |

| Grit | Non Pertinent |

| Hole Configuration | Non Pertinent |

| Micron Grade | Non Pertinent |

| Product Color | Red |

| Product Form | Disc |

| Product Number | PN-DR |

| Substrate | Nickel Alloy |

| Equipment - Machines | Disc Sanders |

| Application | Finishing, Deburring, Radiusing, Refining, Cleaning, Blending |

Frequently Asked Questions

What is the primary application for 3M 7100264196?

The 3M 7100264196 Roloc disc is intended for finishing, deburring, blending, radiusing and cleaning of metal components.

Which attachment system does this Roloc surface conditioning disc use?

This PN-DR medium disc uses the Roloc quick-change attachment for secure, fast mounting on compatible tools.

What machines are compatible with the 3" PN-DR Roloc disc?

The disc is compatible with disc sanders and right-angle grinders that support the Roloc quick-change system at rated speeds.

What substrate is the 3M 7100264196 optimized for?

The disc is optimized for nickel alloys and similar hard metals common in industrial finishing applications.

How does the non-woven backing help performance?

The open non-woven backing resists loading and conforms to surfaces, extending effective service life and finish consistency.

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order