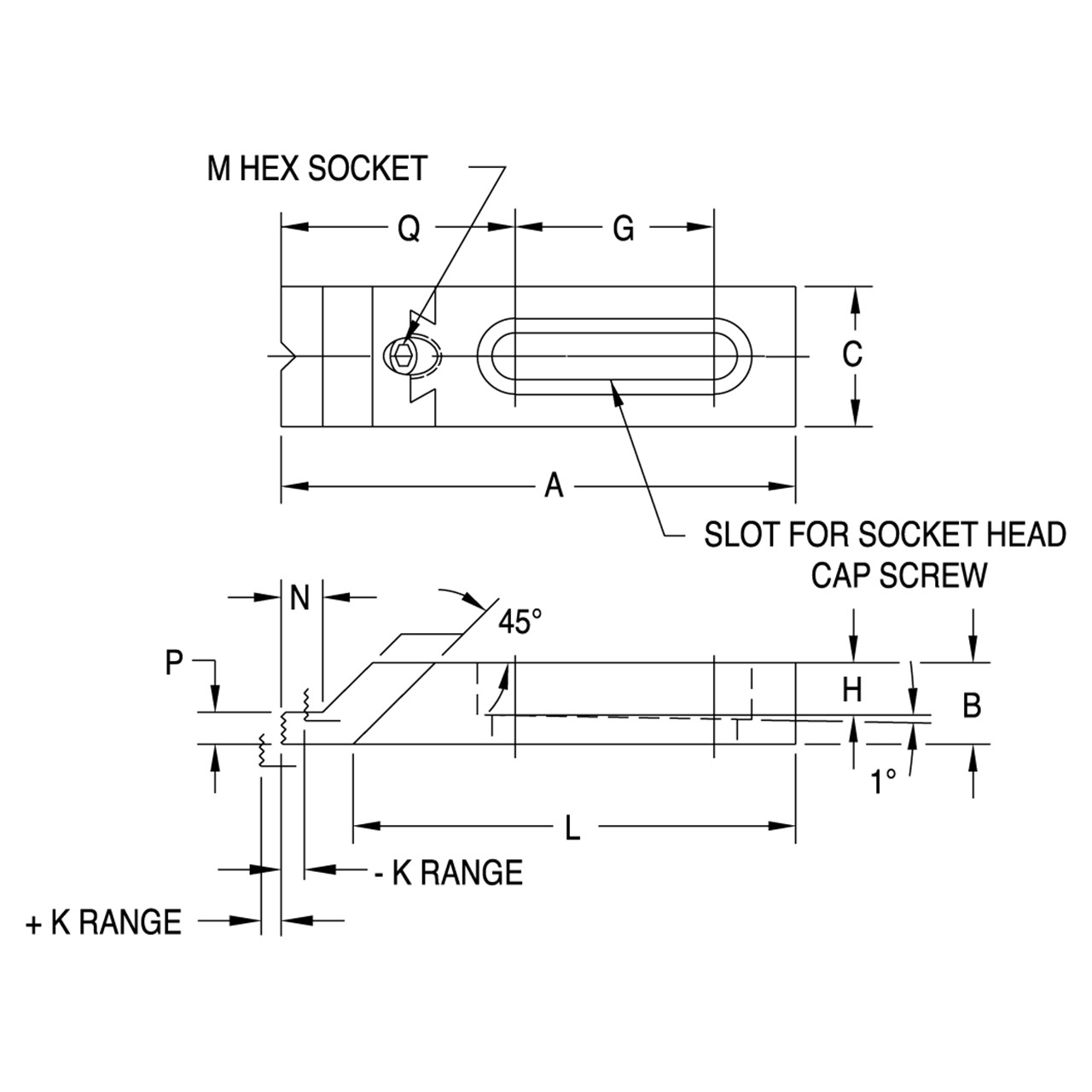

Serrated Adjustable Edge Clamps

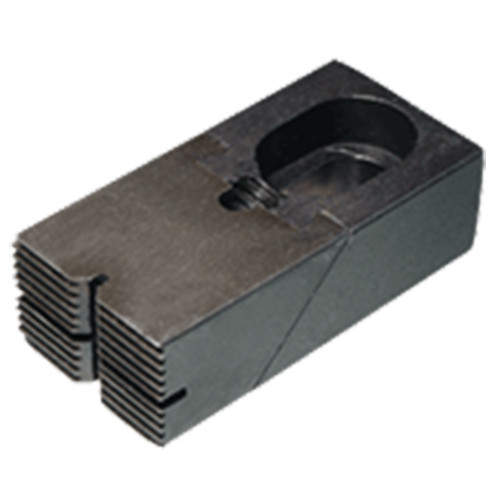

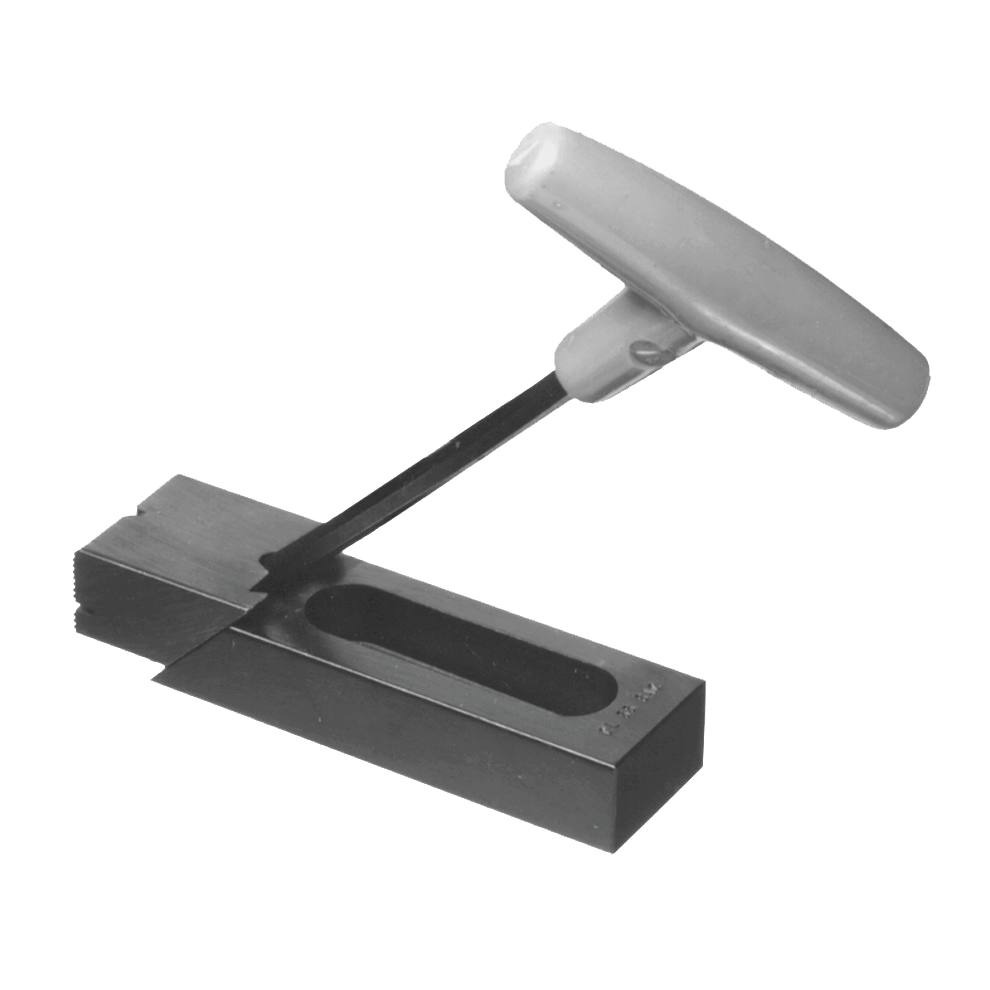

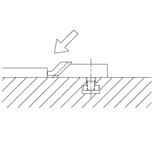

These low-profile clamps are ideal for securely gripping the side of a workpiece to keep the top clear for machining, especially when a large clamping range is required to accommodate workpiece-size variations. The serrated jaw slides at a 45° angle to exert clamping force both forward and downward simultaneously. Clamp by turning the socket-head screw in the sliding jaw with a hex wrench. Choice of low-nose clamping jaw (shown here) or high-nose clamping jaw. V-groove in nose is useful for clamping round parts or corners.The adjustable (slotted) edge clamps shown here are useful for mounting directly on a machine table. The slot is tapered to prevent the clamp from backing off under heavy forces (use two mounting screws on longer clamps). Made in USA.

Application Information

Clamp by tightening the socket-head screw in the sliding jaw with a hex wrench.

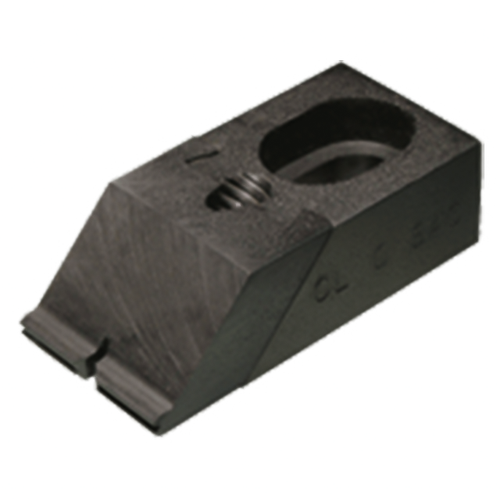

Low-Nose Version

The low-nose version shown here is ideal for thin parts and other applications where extra machining clearance is required.

Material

<

| Item | Material | Heat Treat | Finish | DFARS | RoHS |

| Body and Nose | 1018 Steel | Carburized Hardened | Black Oxide | ✔ | ✔ |

| Clamping Screw | 4140 Steel | Heat Treated Rc 43-45 | Black Oxide | ✔ | ✔ |

Parts Specification

| Mounting Screw Size | A (Inch) | B (Inch) | C (Inch) | G (Inch) | H (Inch) | K (Inch) | L (Inch) | M (Inch) | N (Inch) | P (Inch) | Q (Inch) |

| 1/2-13 or M12 | 7-1/4" | 7/8" | 1-1/2" | 3" | 1/2" | 5/16" | 6-5/16" | 1/4" | 1/4" | 1/4" | 2-9/32" |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order