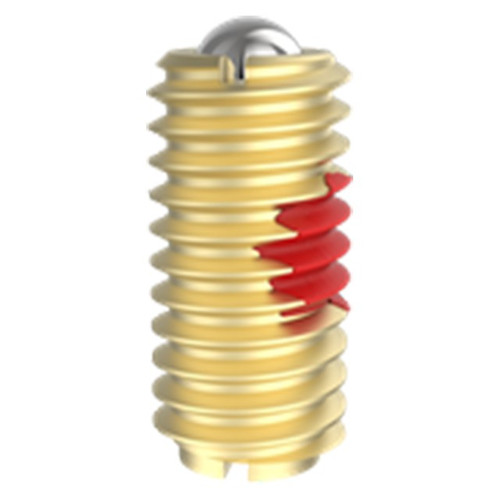

Spring Plungers-Steel

This standard-length, threaded type has a long stroke and long plunger bearing length for smooth operation. It has a steel body and a hardened steel plunger nose. Made in USA.

Install and/or adjust from either end. When using the slot at the plunger end to install, use a Plunger Wrench instead of a screwdriver to avoid over-compressing the spring. A thread-locking element holds the unit securely in place after installation.

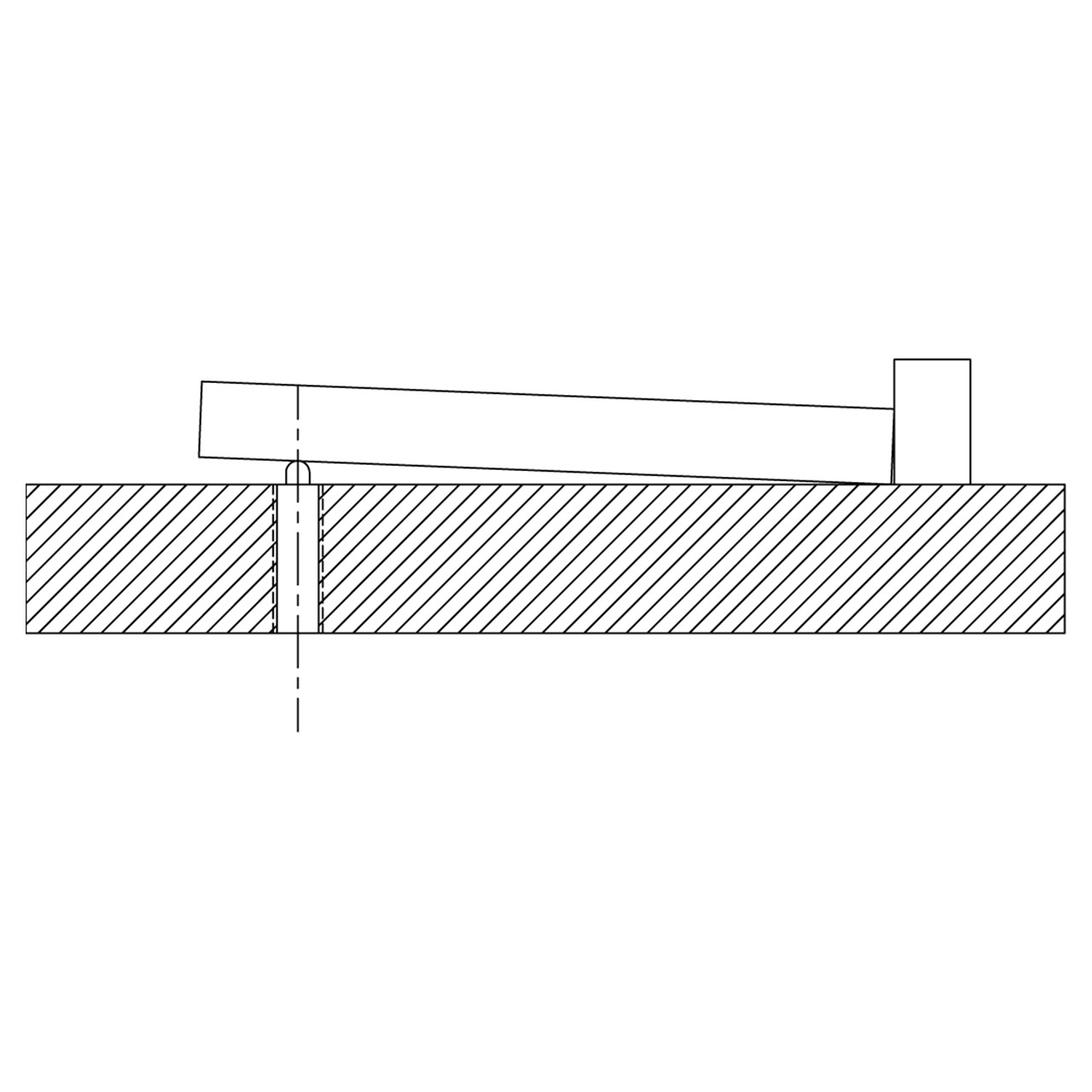

Application Information

Spring plungers can be used to lift parts slightly after machining, for easier unloading.

Internal View

Nose Extended

Nose Retracted

Material

| Item | Material | Heat Treat | Finish | DFARS | RoHS |

| Body | 1215 steel, black oxide Finish (Metric sizes zinc plated clear chromate) | - | - | Yes | Yes |

| Plunger Nose | 1215 Steel | Carburized-Hardened | black oxide Finish (heavy force) or zinc plated clear chromate (light force) | Yes | Yes |

| Spring | Music Wire | - | - | Yes | Yes |

Parts Specification

| A Thread | Thread Pitch (mm) | Initial End Force (n) | Final End Force (n) | B (mm) | C (mm) | D Diameter (mm) |

| M10 | 1.5 mm | 24 N | 64 N | 28.5 mm | 4.8 mm | 4.72 mm |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order