Product Information

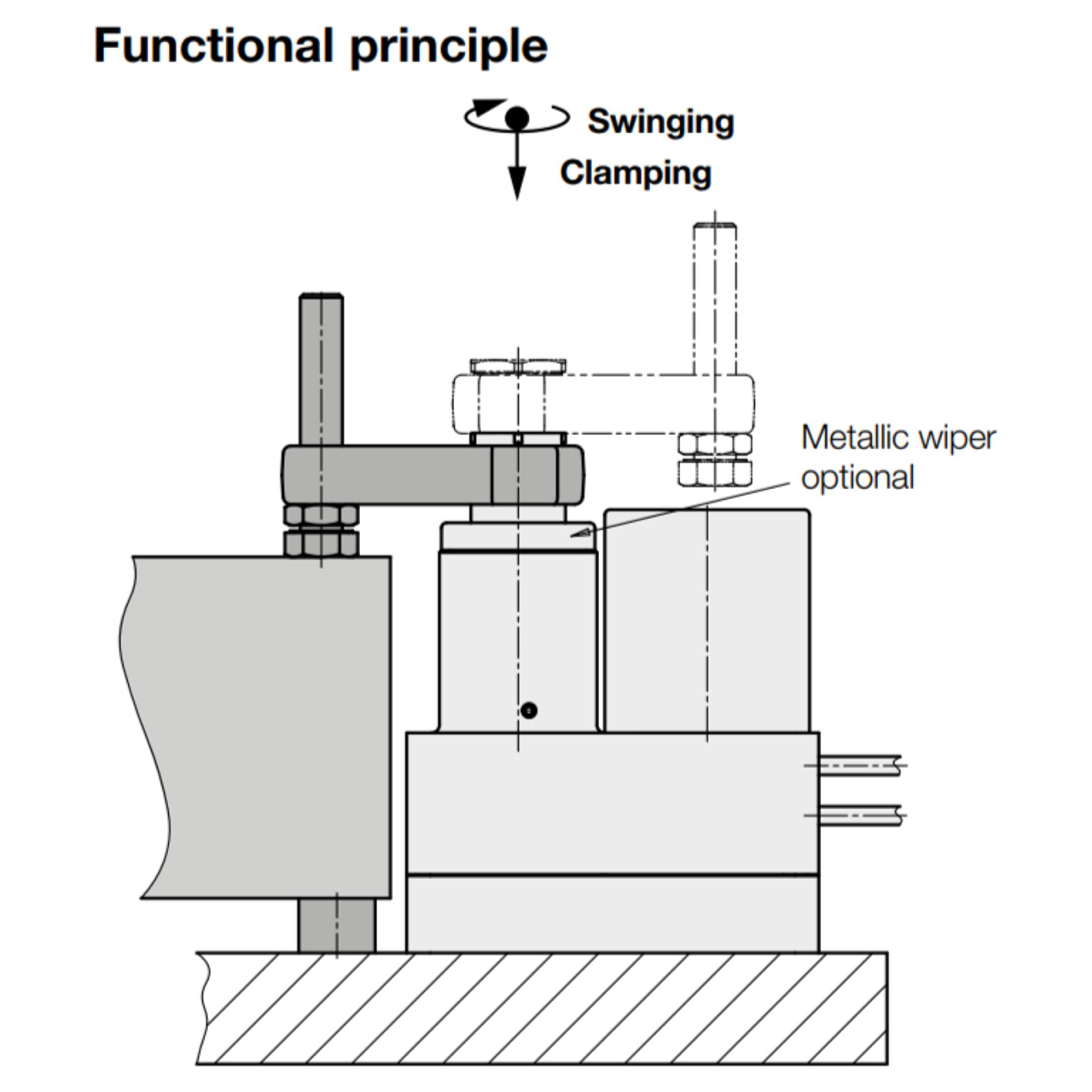

The electric swing clamp is driven by a wear-resistant brushless DC motor. The motor speed is transformed by means of a gear and a threaded spindle into the swing and stroke movement of the piston rod. During the 180 Degree swing of the clamping, an axial stroke of only 3 mm is required. If the clamping arm collides during the swing motion with a workpiece, the mechanism is protected against overload. The direct current motor is automatically and immediately switched off. When unclamping, the clamping arm always swings back to the off-position. BENEFITS • High clamping force• Adjustable clamping force• Clamping force monitoring• FAILSAFE - High operating safety by a self-locking spindle drive• Mechanical re-clamping by Belleville springs• Swing angle up to 180 Degree available• Overload protection device in the case of collisions with the clamping arm• Electric position monitoring and extensive self-monitoring with diagnostic options• Clamping stroke control possible• Low voltage 24 VDC• Maintenance-free (500,000 cycles).• Code class IP 67

Application Information

Electric swing clamps are used for clamping or holding of workpieces- when the clamping and holding points shall be free for loading and unloading of the fixture- when an extended functionality is required for automated systems- when clamping elements have to be controlled individually- where the clamping force must be maintained also after the separation from the energy supply Thus, electric swing clamps are particularly suited for: Packaging industry Test systems Special machines Assembly equipment and robotics Automatic manufacturing systems Clamping fixtures with workpiece loading via handling systems

Videos

Roemheld's Electric Swing Clamps Get safe, high clamping force, as well as adjustable clamping force.

Function, Power & Control Info

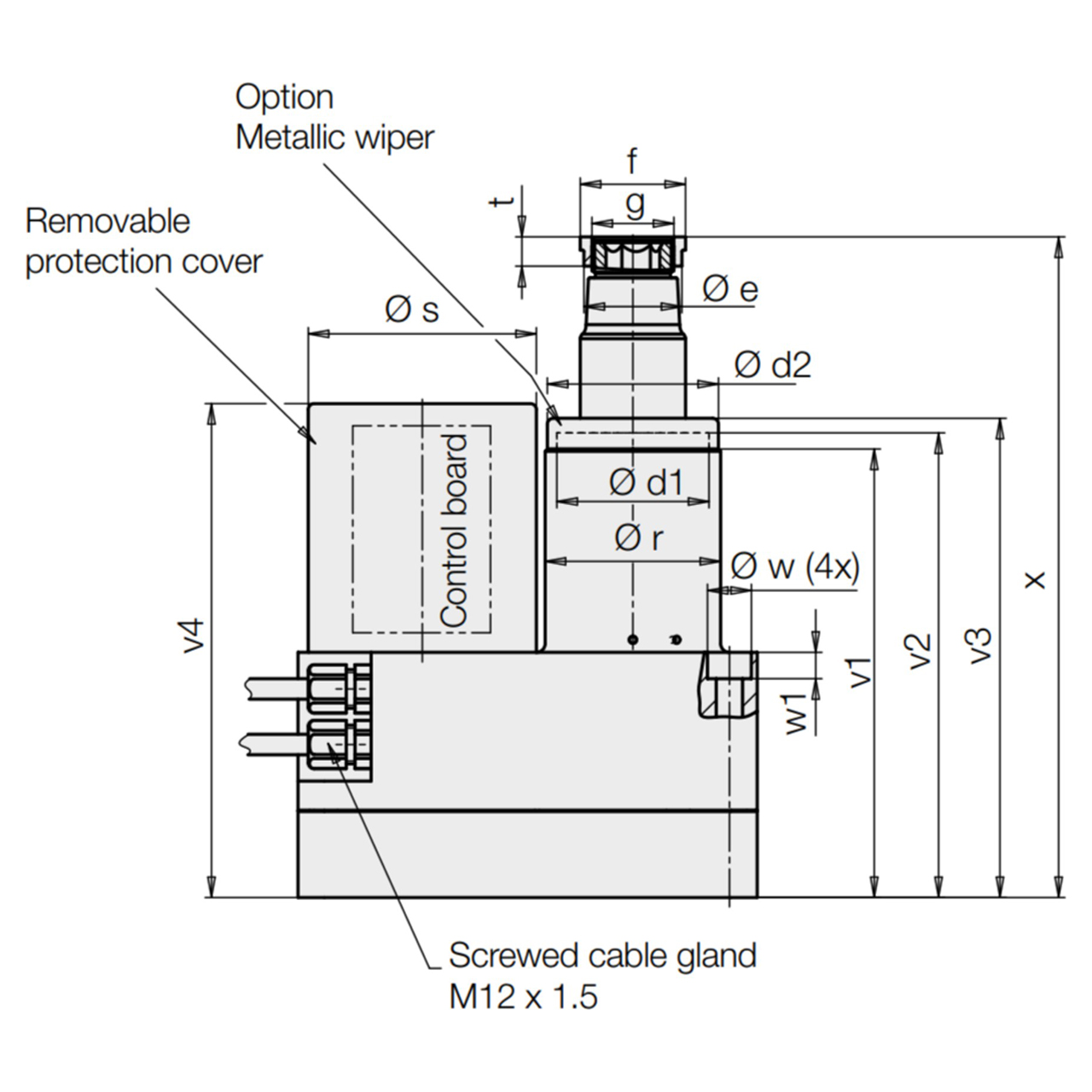

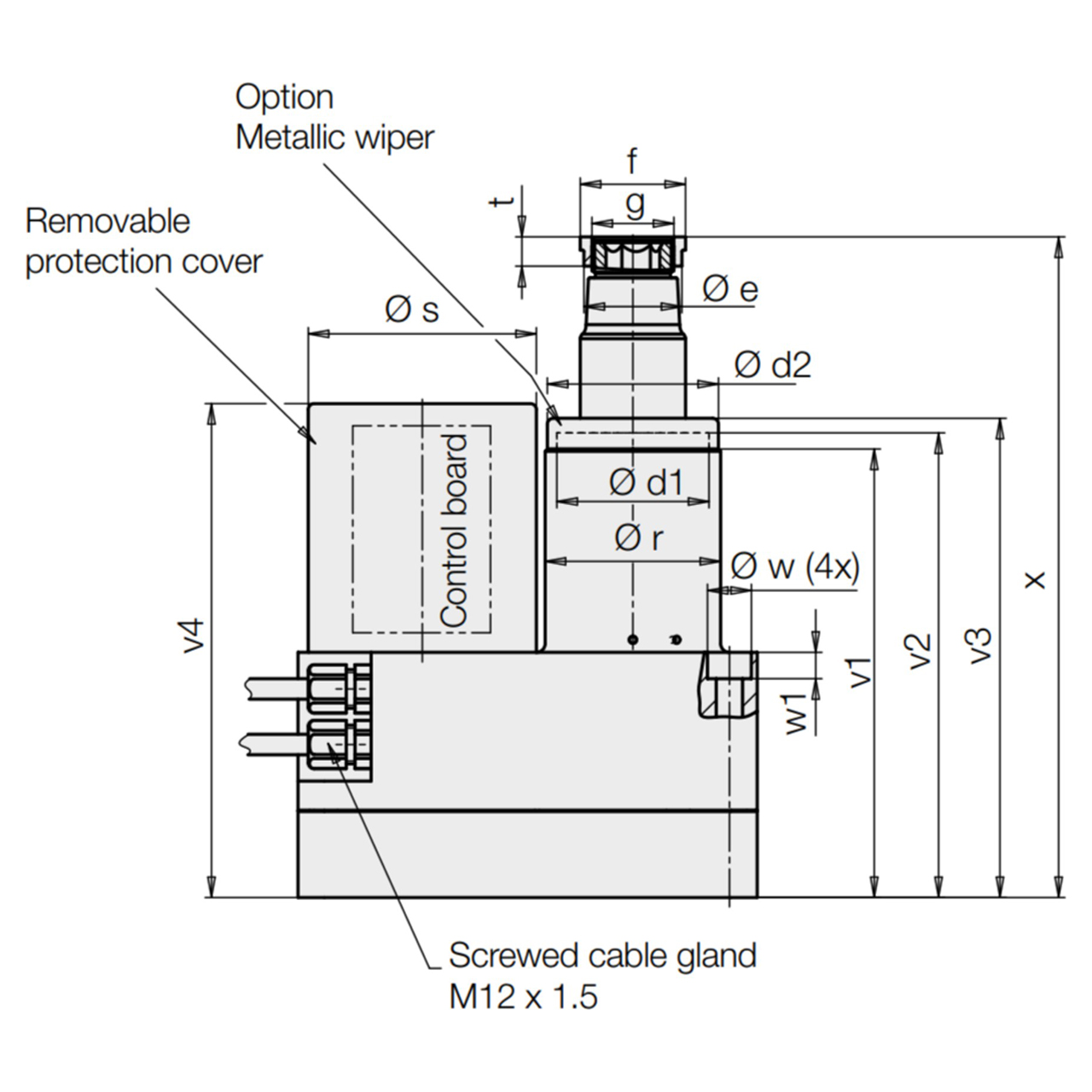

Integrated control The electronic control for the DC motor is on a board in the housing of the electric swing clamp. Electric connection Power supply and signal exchange for external control are transmitted by two short cables with plug-type connector. Cable sockets are available for the customer's connection (see connection accessories).Safe touch voltage The 24 VDC voltage is considered to be a "low voltage" and thus it is not dangerous for people in case of contact. Power supply For motor and electronic control a DC voltage of 24 V with a residual ripple of max. 10 % is required. For the DC motor, we recommend the use of a switching power supply with a current output of 15 A per connected electric swing clamp. When operating several swing clamps at the same time, the line is to be enlarged correspondingly. The electronic control has to be supplied by a separate power supply (24 V DC/100 mA).Adjusting ranges After removal of the protection cover, the following adjustments can be made on the control board:• Clamping force• Swing speed• Compensation of the clamping arm elasticity The clamping force can also be adjusted via analogue input. Integrated Feedback Unclamped• Clamping arm in off-position and unclamping process completed Clamped• Clamping arm within clamping area and clamping force obtained• Clamping stroke control possible by output signal Diagnostic options• Extensive review on error conditions• Signalling via error code (flashing signal) internally on control board or via external interface signal• Error messages can be reset• Review display after 500,000 cycles You will find a complete description in the supplied operating manual.

Material

| MATERIAL | HEAT TREAT | FINISH |

| Steel | - | Black Oxide |

Parts Specification

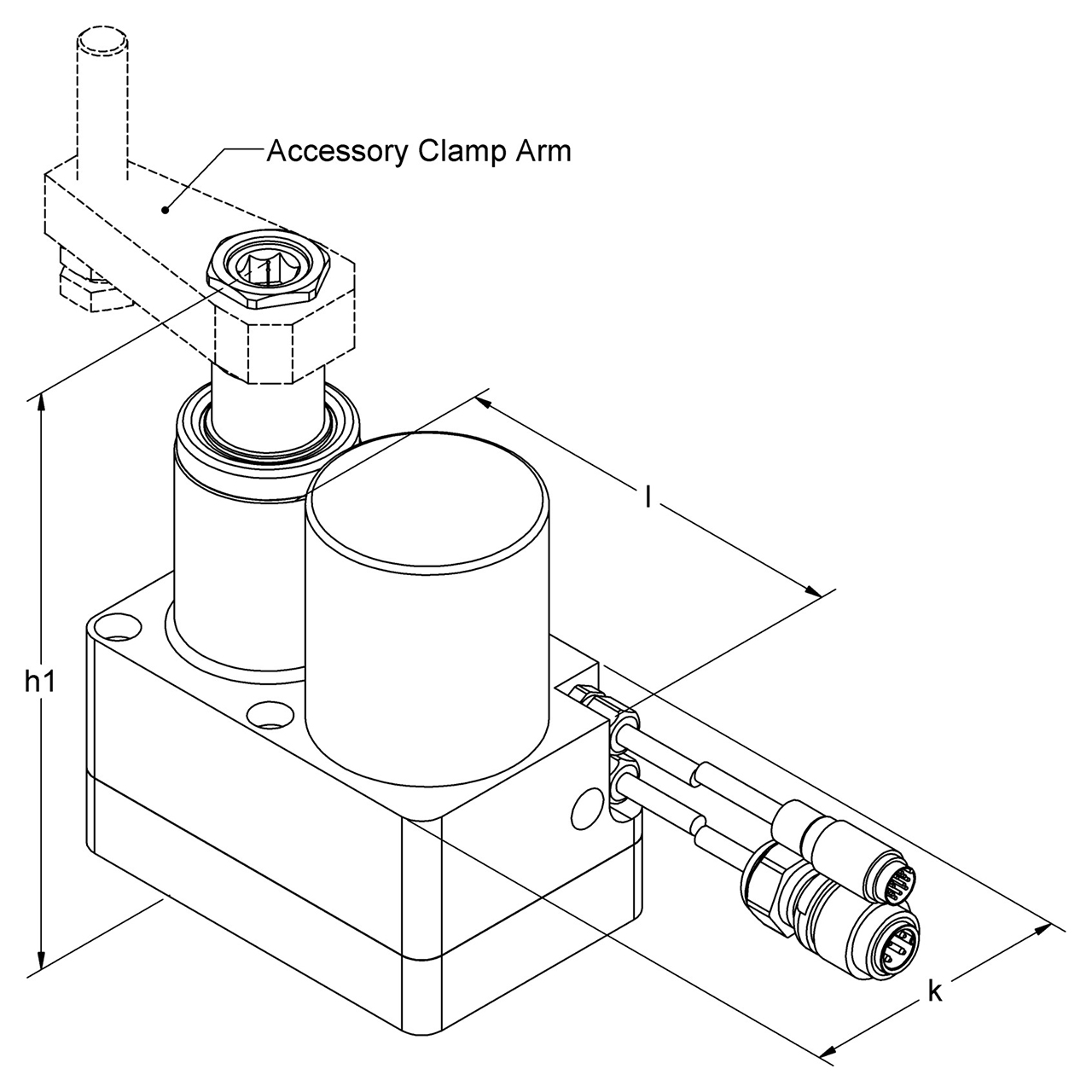

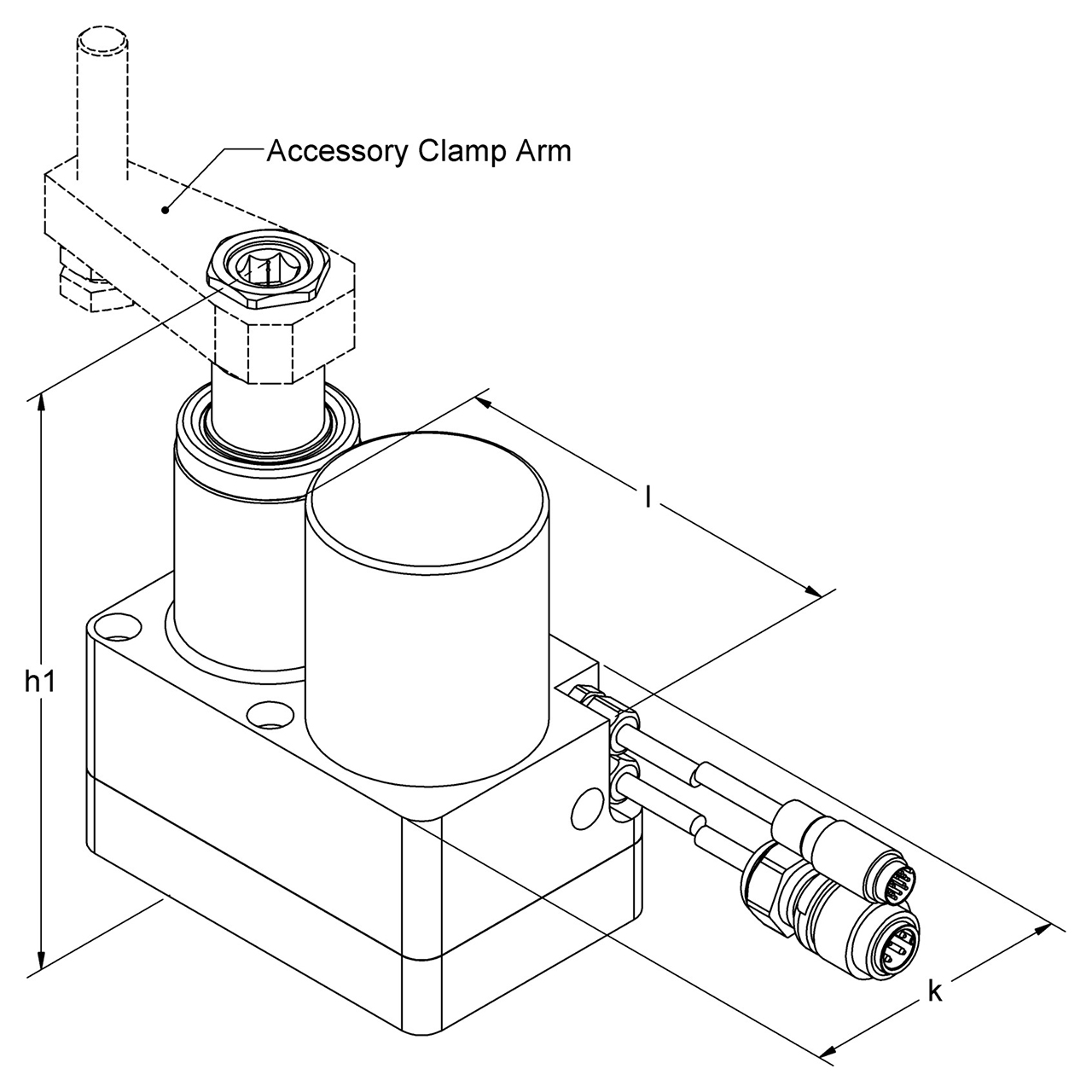

| Part Number | Connection Type | Swing Angle & Direction | Clamping Force (lbs) | Clamping Force (kN) | Clamping Stroke (mm) | h1 (mm) | l (mm) | k (mm) | Weight (kg) | Full Technical Details | IMPORTANT REQUIREMENT |

| CLR-1835-C090-R26PMI | IO-Link | 90 Degree Right | 1776 | 7.9 | 20 | 225.8 | 157 | 105 | 10.75 | See Data Sheet | Completed Checklist found under Documents accordion is required before a quote can be processed. |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order