Product Information

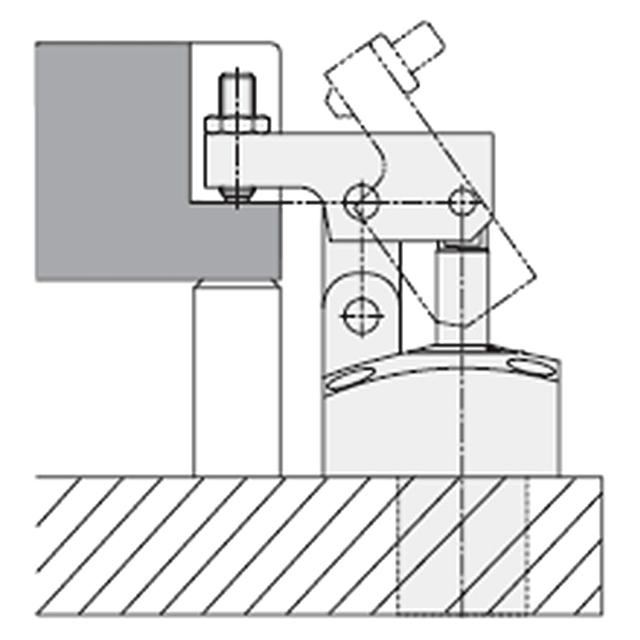

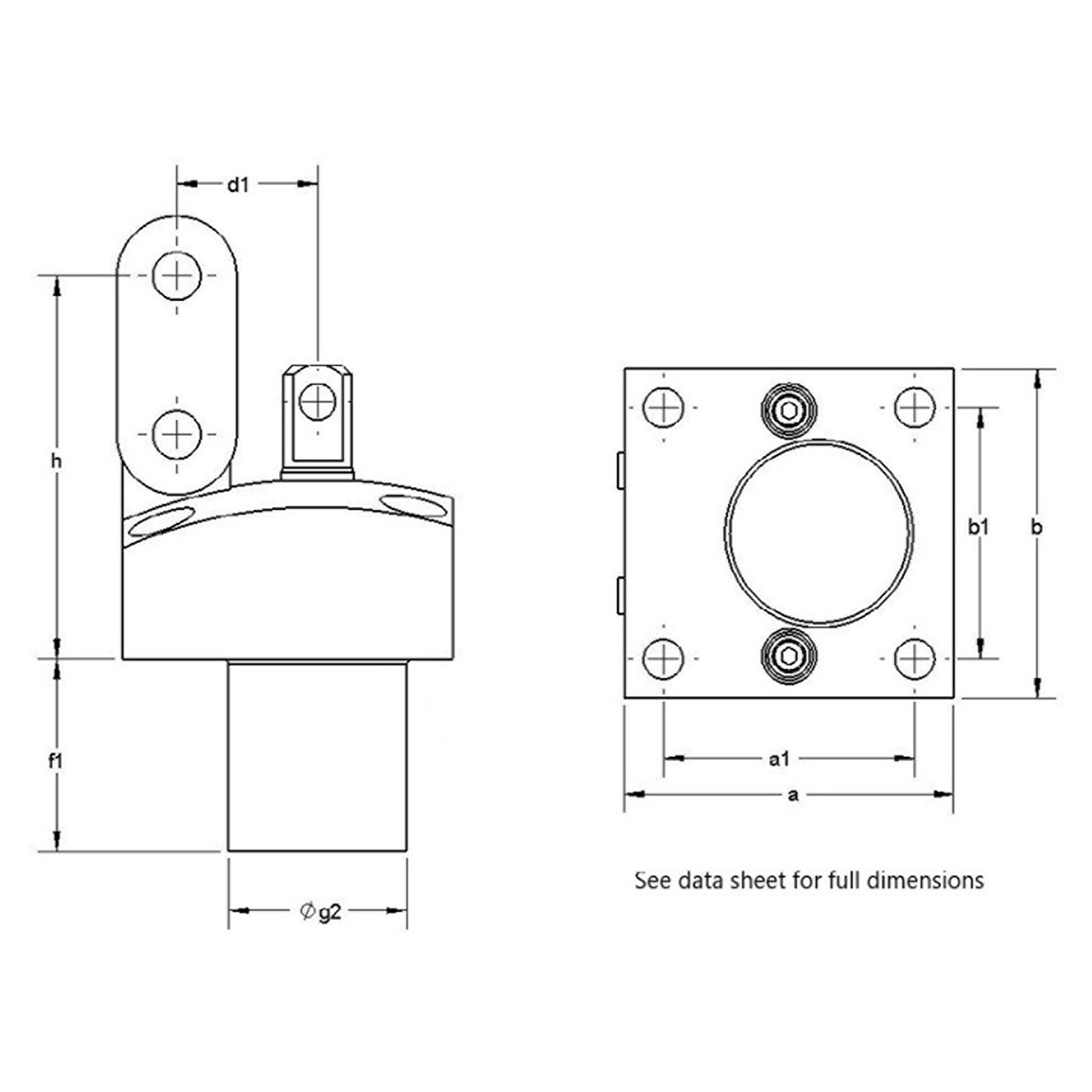

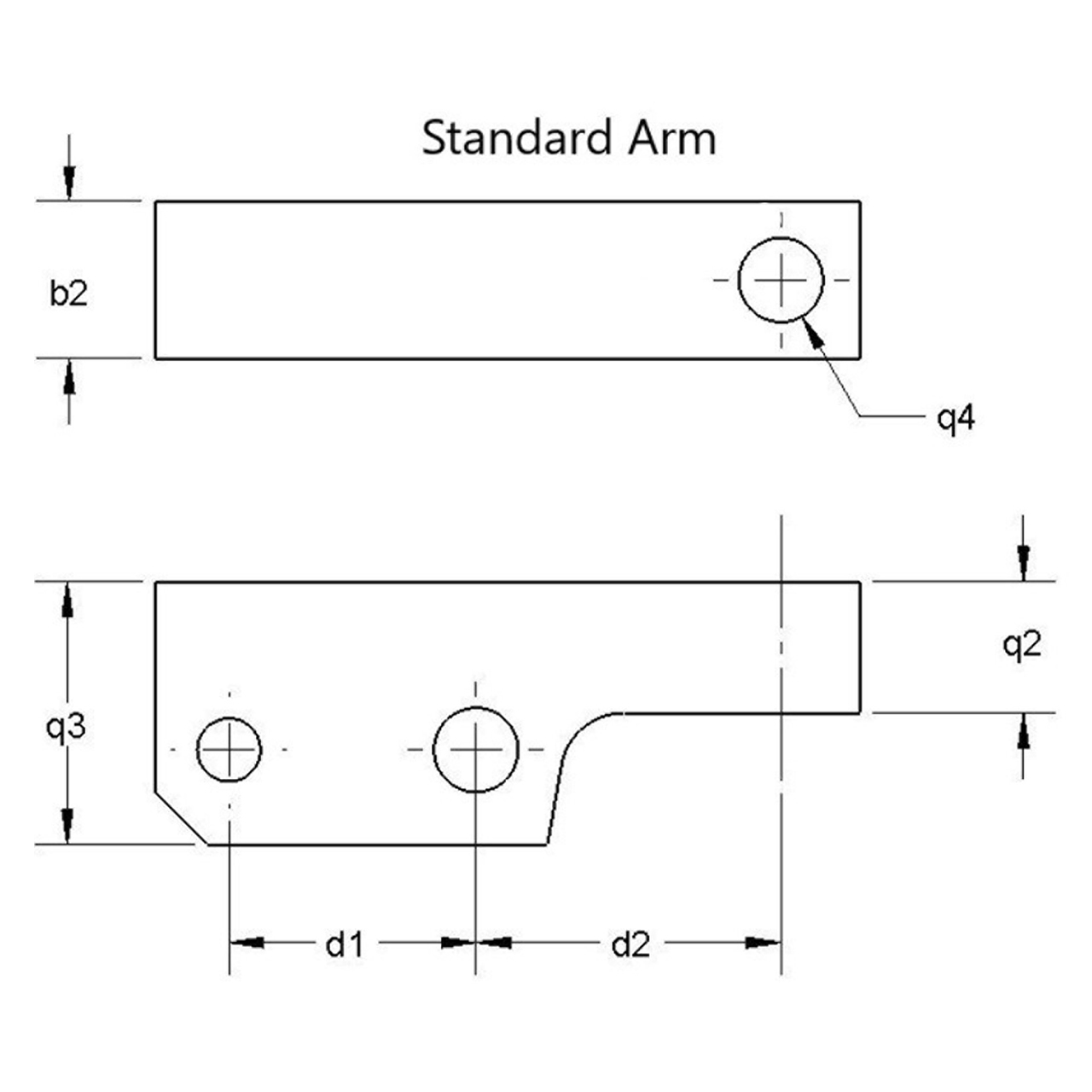

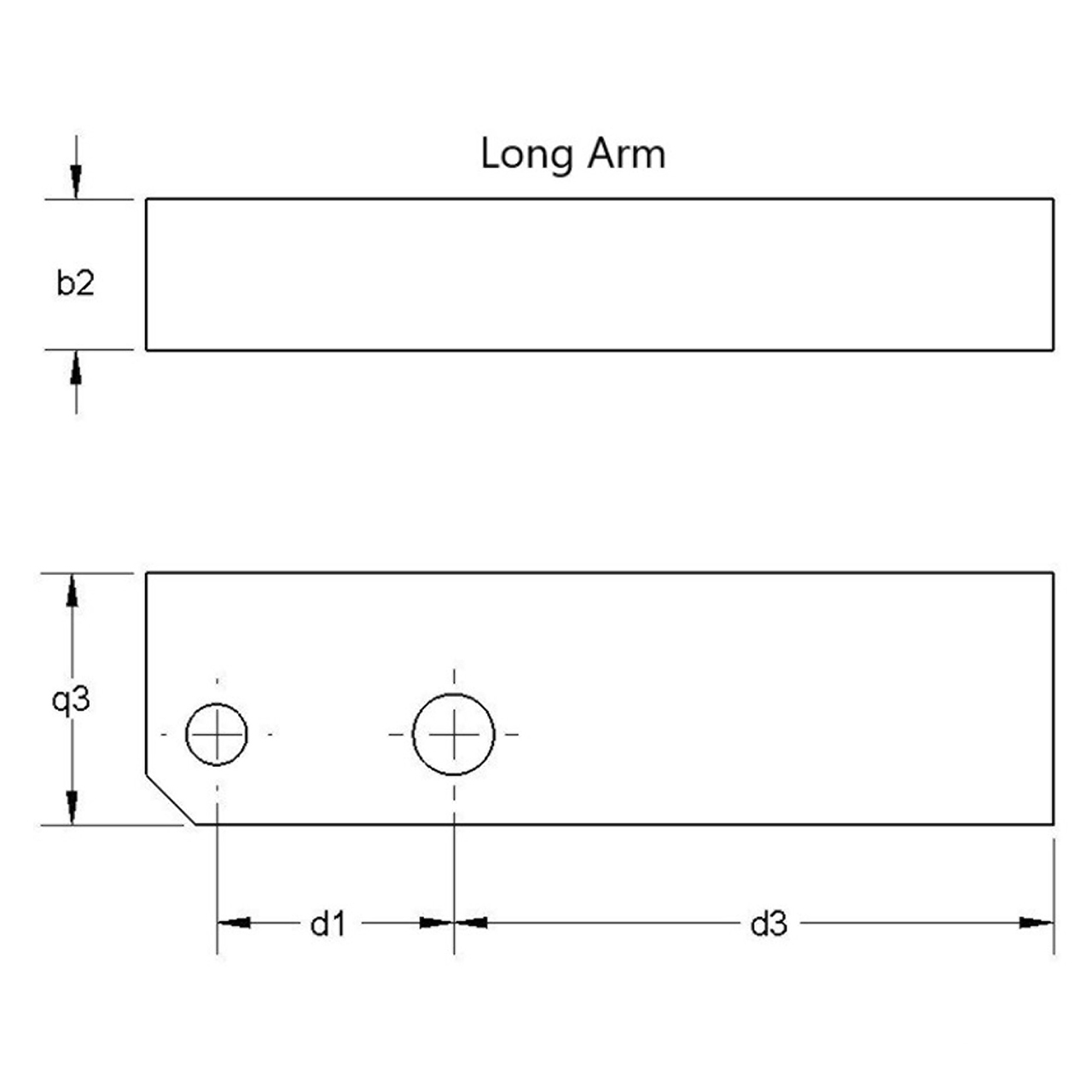

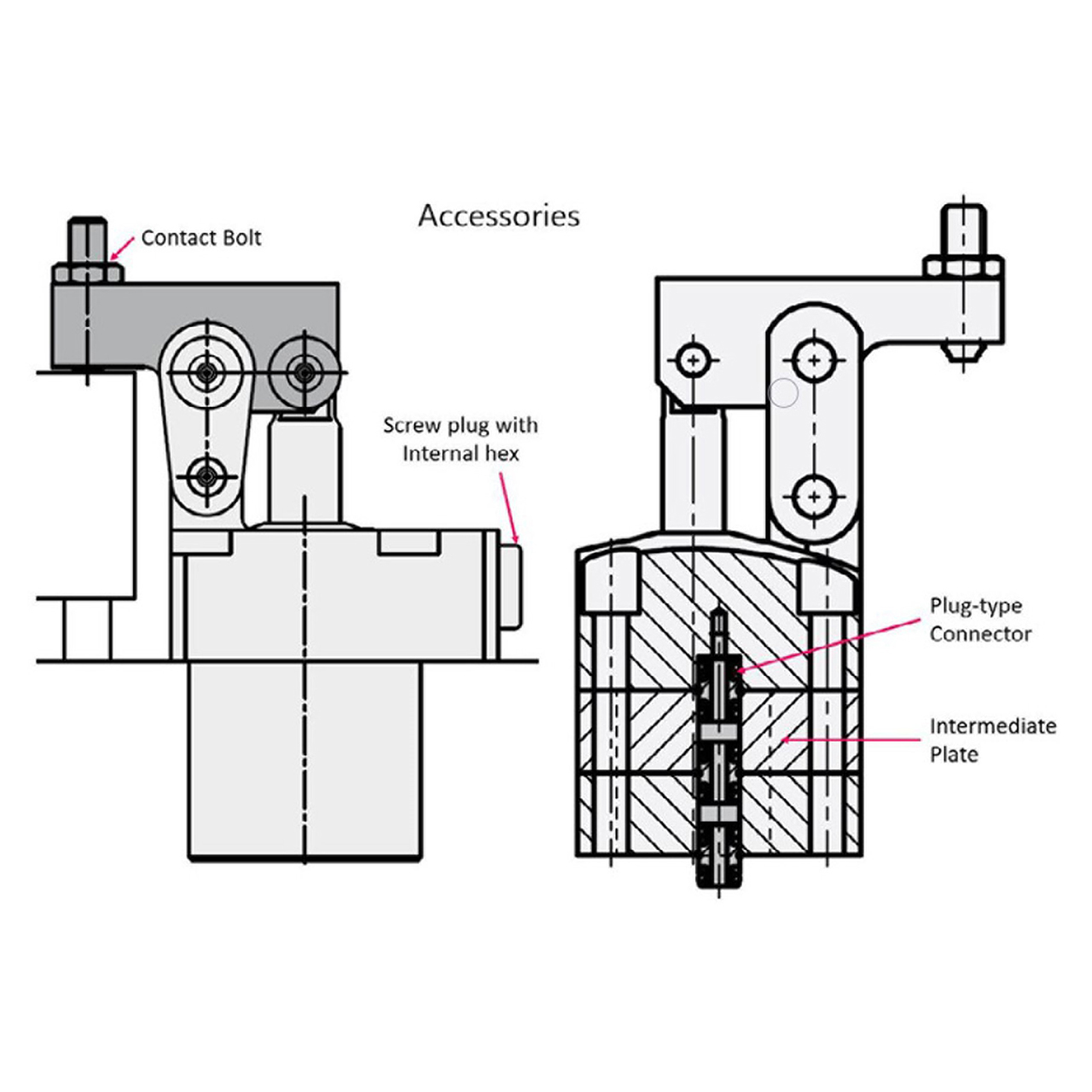

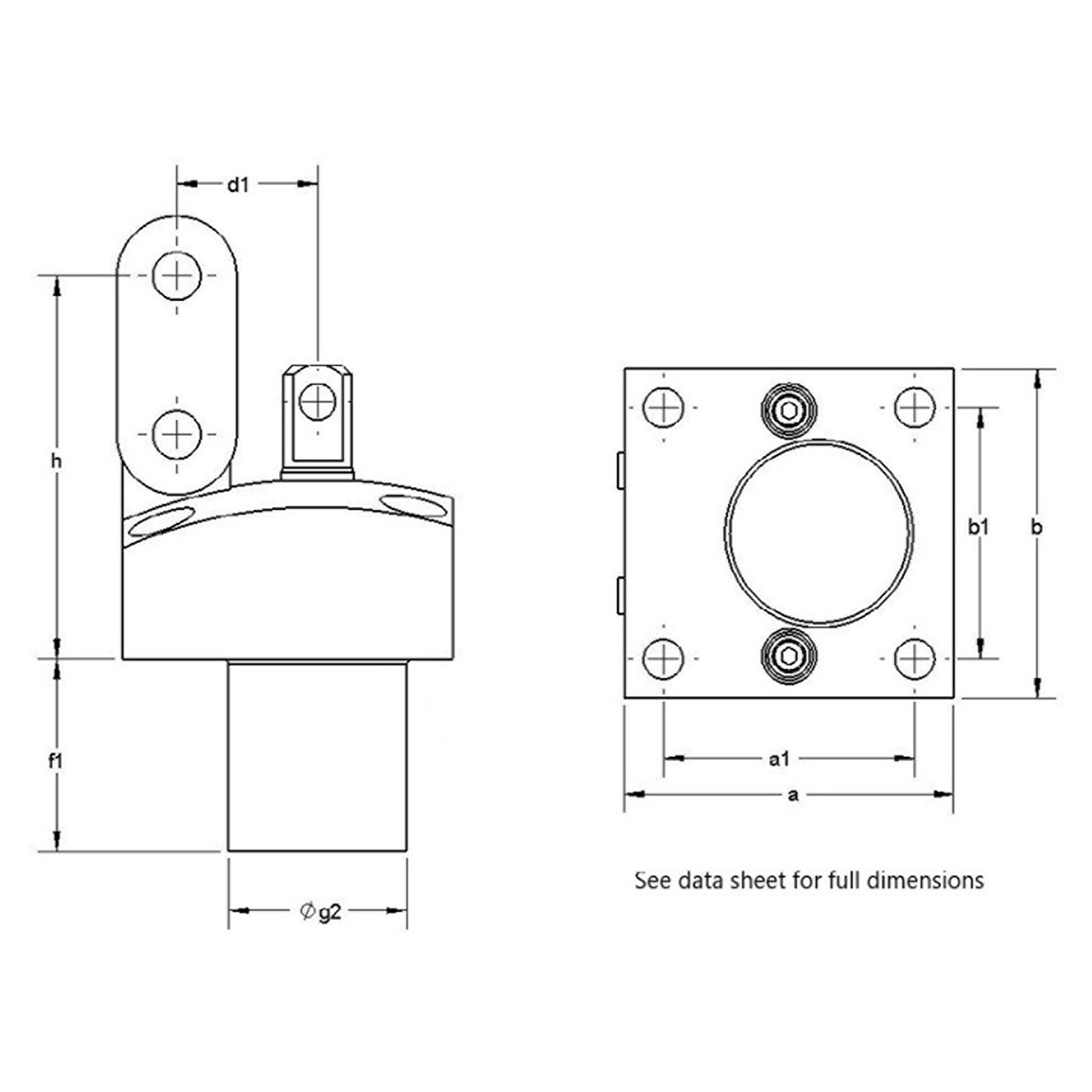

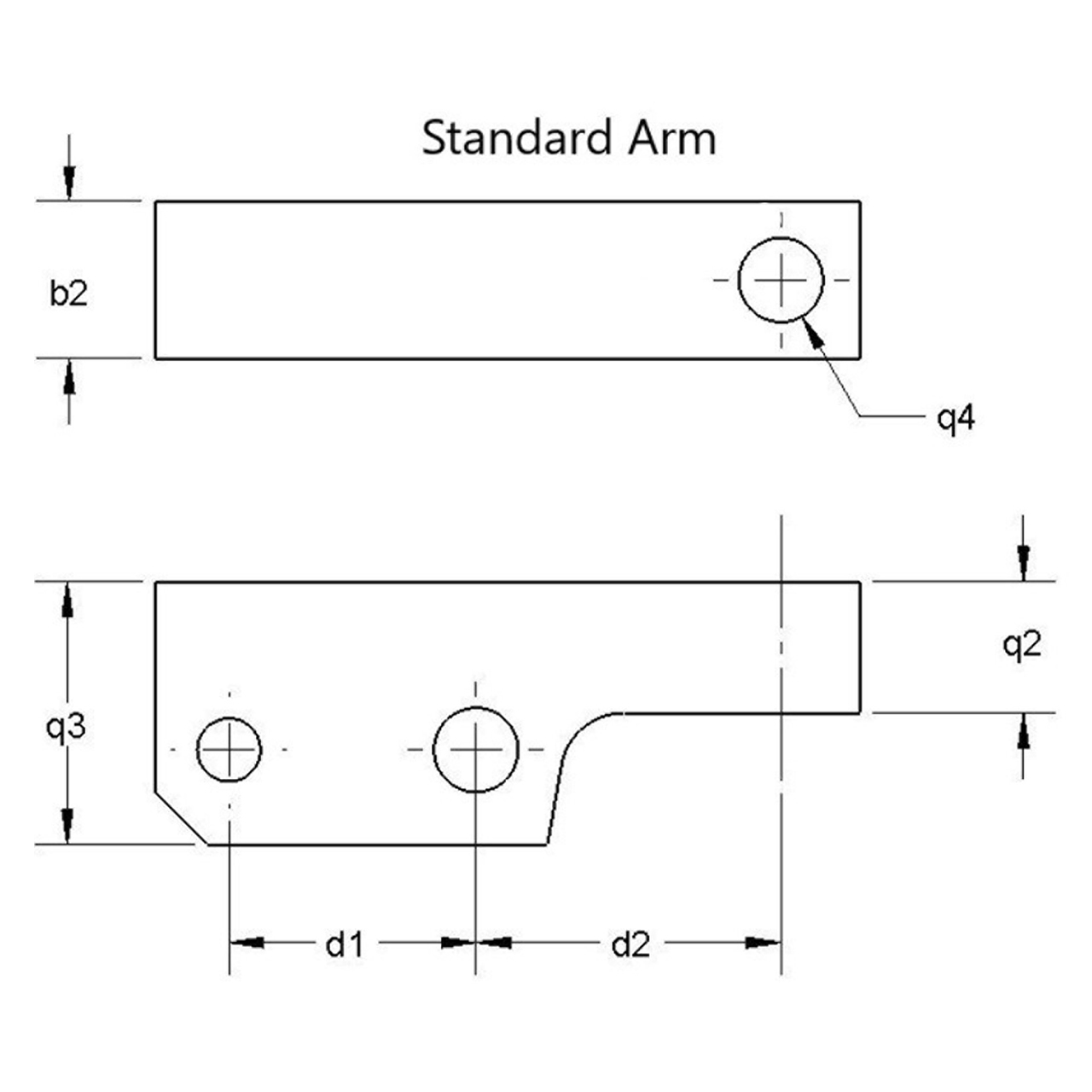

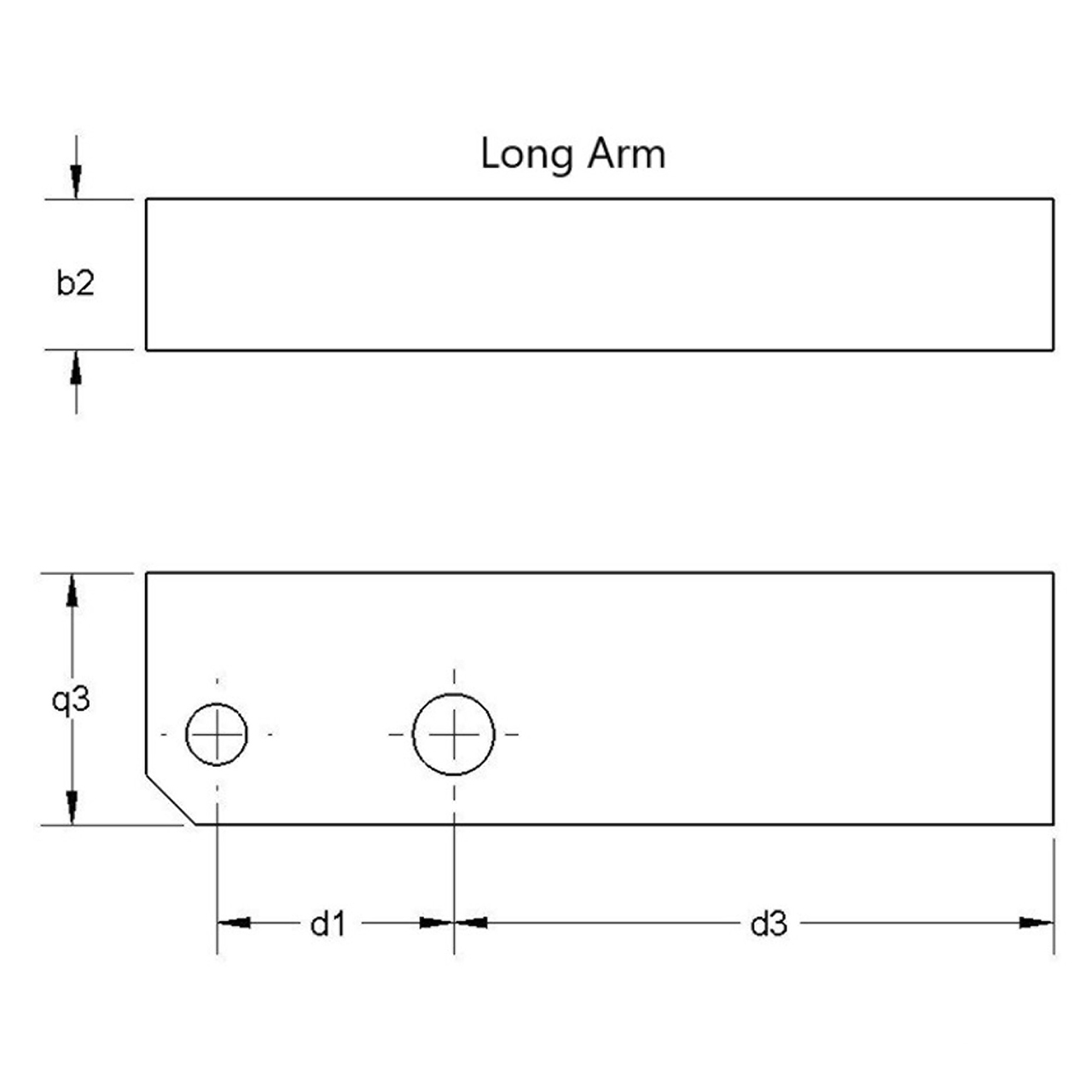

3600 psi max Double Acting Hinge Clamps have a sturdy linkage configuration that moves the clamping arm forward as it pivots into clamping position. This specially designed linkage allows the clamp to exert nearly perfectly vertical clamping force. The clamping arm retracts fully for clear loading from above. Ideal for clamping in narrow recesses. Durable, economical clamp with an easy-to-clean mechanism and standard metallic wiper. The top-flange version shown here is designed specifically for space-saving manifold mounting. Available in four clamp sizes, double acting only, each with either a standard clamping arm with swivel contact bolt, a long clamping arm for customization, or without a clamping arm for a user-manufactured arm. Clamping force at 3600 psi with standard clamping arm: 850 Lbs 2200 Lbs 3200 Lbs 4800 Lbs

Clamping Action

Applying fluid pressure to the A (clamping) port advances the piston, which is connected to the clamping arm. The arm moves forward as it pivots into position via a linkage. Switching pressure to the B (unclamping) port positively retracts the piston and the attached clamping arm.

Design Considerations

The ideal clamping height in most cases is "H", because arm motion is totally vertical at that height. This avoids applying any horizontal force to the workpiece during clamping.

Mounting & Fluid Supply

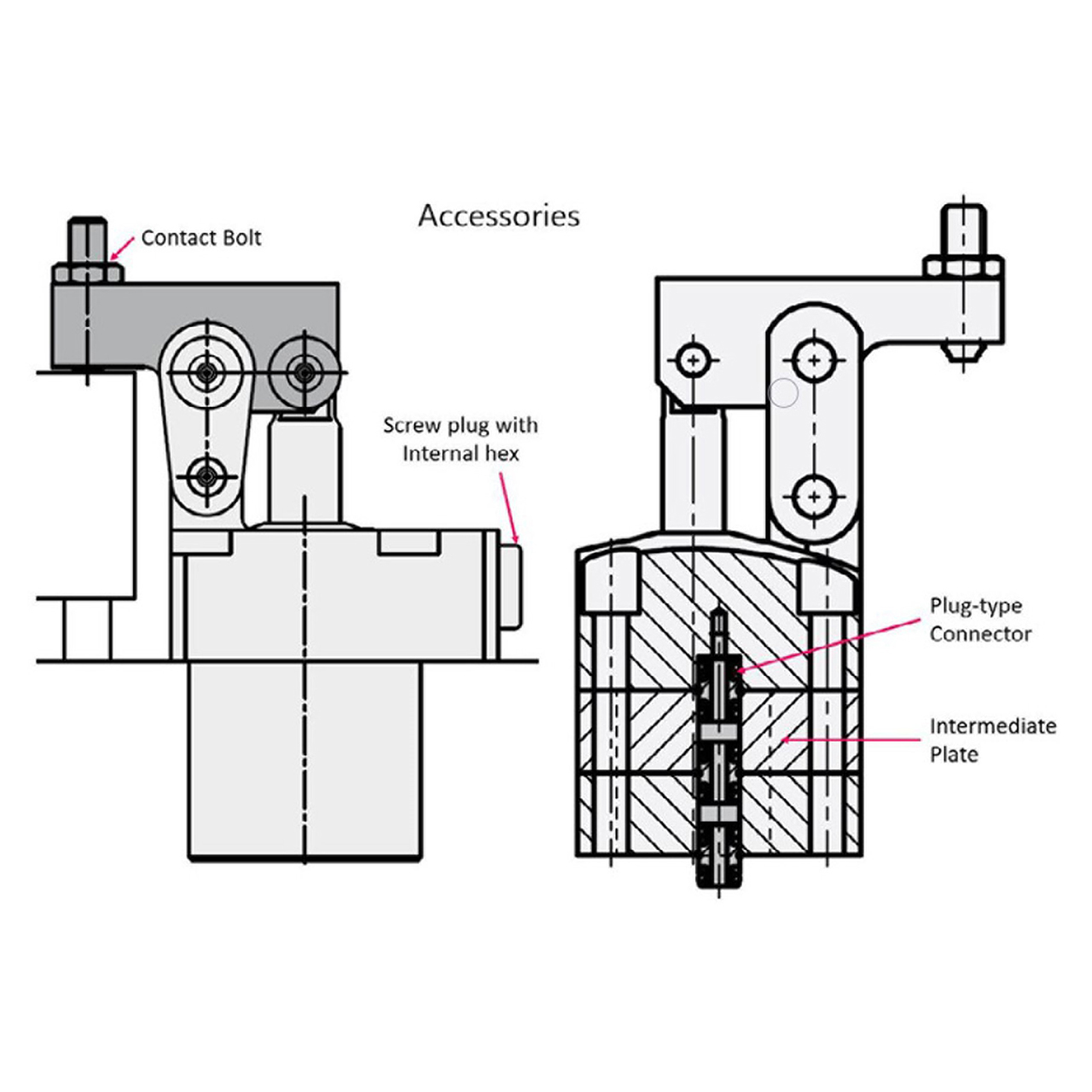

For low mounting, install cylindrical base in a bored hole, then fasten top flange with four socket-head cap screws. For high mounting, use optional intermediate plate with four longer socket-head cap screws. Version 1: Two 1/8" BSPP or 1/4" BSPP ports, A for clamping, B for unclamping. For optional manifold mounting, use the A and B manifold ports underneath the clamp by unscrewing the sealing plugs and installing two CLR-9210-145-F Connecting Inserts (also install two CLR-901-F Port Plugs in the 1/4" BSPP ports). Do not use NPT fittings. Version 2: Two 1/8" BSPP or 1/4" BSPP ports, A for clamping, B for unclamping – on any of three sides. Do not use NPT fittings.

Optional Position Sensing

These clamps can be ordered with an extended piston rod for inductive or pneumatic position monitoring. For inductive position monitoring, order an inductive monitoring end cap (separately or already installed), two CLR-3829-198-PM inductive proximity switches, and two CLR-3829-099-PM right-angle push plugs with cable. For pneumatic position monitoring, order a pneumatic monitoring end cap (separately or already installed). Monitoring devices can be turned to any of the four sides.

Material

| MATERIAL | HEAT TREAT | FINISH | DFARS | RoHS |

| Steel | - | - | ✔ | ✔ |

Parts Specification

| Part Number | CLAMP SIZE | b2 (mm) | d1 (mm) | d2 (mm) | q2 (mm) | q3 (mm) | q4 (mm) | WEIGHT (LBS) |

| CLR-3548-1035 | 4 | 30 | 43.5 | 60.5 | 28 | 55 | M16 | 3.19 LBS |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order