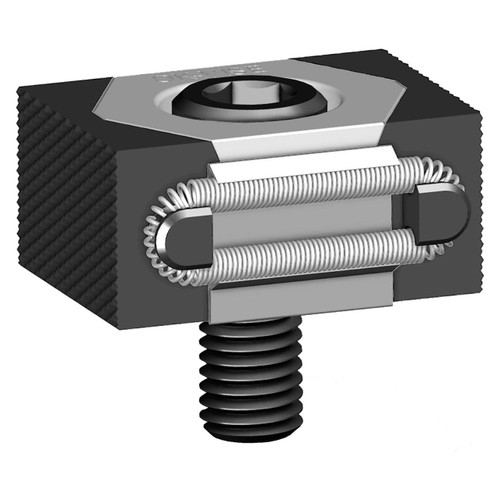

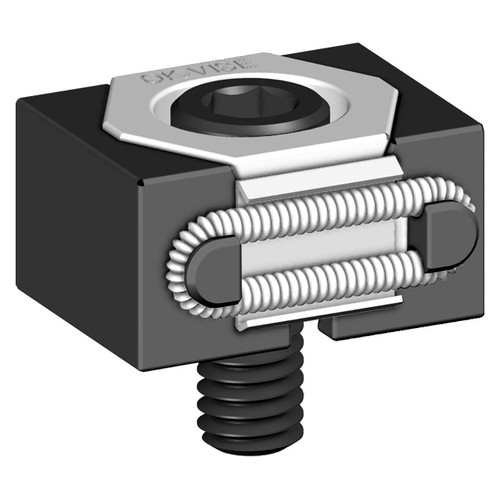

THREE-DIMENSIONAL MACHINING - Due to a low-profile design of OK-VISE Clamps, it is possible to execute flexible three-directional machining of workpieces with one fastening. This ability to machine a workpiece in three planes means improved accuracy.

PULL DOWN ACTION - The single wedge clamps keep the workpieces steadily in place, not allowing upward or downward movement. The double-wedge clamps generate a pull-down action pressing the workpieces towards the fixture base.

MACHINABLE JAWS - Single-wedge clamps are also available with extended jaws that can be machined to suit the geometry of the workpiece.

SPECIAL MODELS - "E": (Balls on each Jaw) A self adjusting serrated steel ball is helpful when clamping castings and workpieces of irregular shape. "T": Jaws tapped with M5 threads for socket head screws allowing for quick and easy use of various different additional pieces. "SS": BK2 is high quality stainless steel to meet the demands of EDM applications.

ECONOMY MODEL - "O": Not ground as precise as standard models. Same raw material is being used and the bottom of the jaws are ground for precise locating on the fixture base.

| Screw Size | 5/8-11 |

| Maximum Torque | 250 ft/lb |

| Holding Force | 22000 lbs |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order