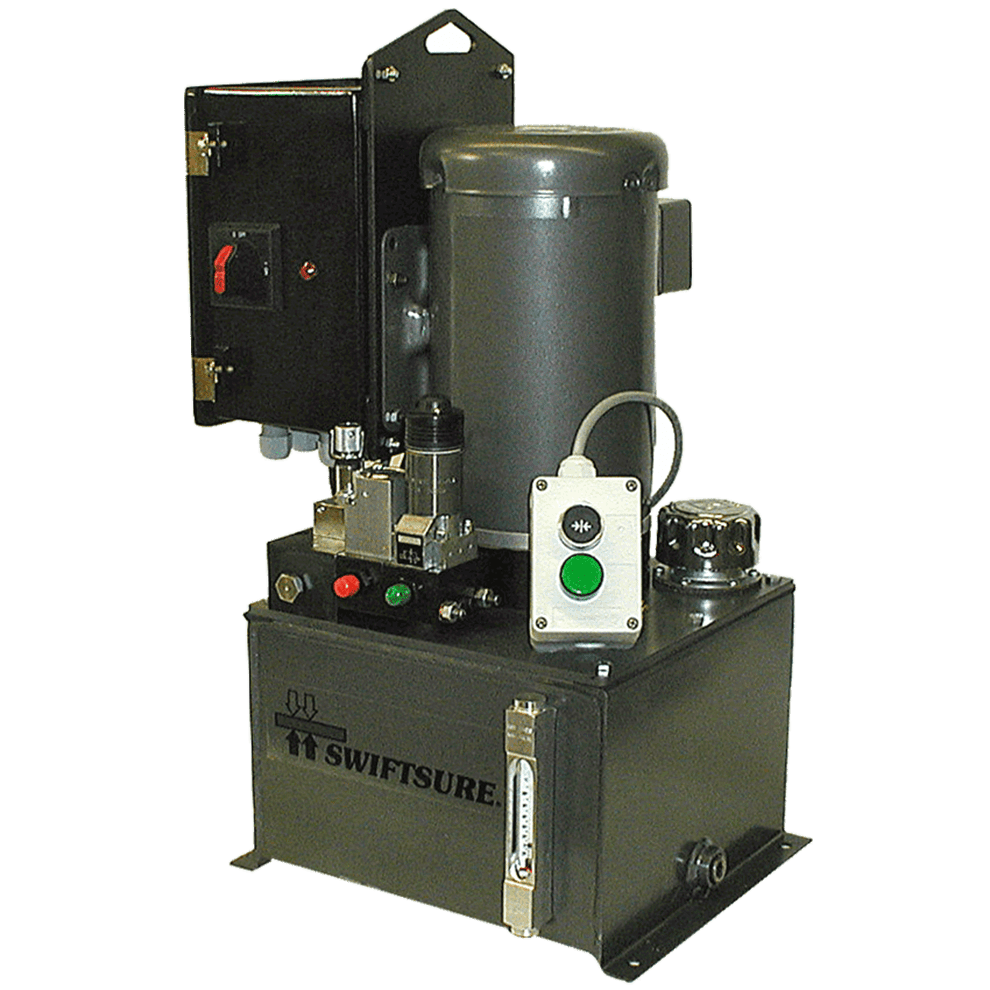

Roemheld Electric Power Units Standard

7250 or 5000 psi maxFor Single-Acting and Double-Acting Systems

Electric Power Units are the best power source for most workholding applications, complete with all electrical and hydraulic controls. Quiet, long-life radial piston pump powered by a totally enclosed fan-cooled universal motor. Large reservoir provides enough fluid capacity for virtually any fixture. Leak-free poppet valves and fittings.

Control Options

Standard ControlsThe standard configuration has one remote push-button clamping switch. The single-acting version has one solenoid-operated clamping valve, to provide one clamping-pressure port "A" and a return port "R" (return port is required when separate clamping valves are used to clamp multiple workpieces independently-leave the push-button switch in "clamped" position so that the "A" port supplies constant pressure). The double-acting version has two solenoid-operated clamping valves, providing one clamping pressure port "A", one unclamping-pressure port "B", and a return port "R".

Operation

The heart of this unit is a precision, long-life radial-piston pump controlled upon demand by an integral pressure switch. This switch is infinitely adjustable from the minimum to the maximum operating pressure. Automatic pressure control is assured, because the pump restarts if pressure drops. Clamping pressure is assured even with an electrical power failure since the solenoid valves are mechanically held in "clamped" position, requiring power only to unclamp. The poppet design of these valves ensures positive, leak-free sealing.

Mounting & Setup

Mount power unit upright, preferably above fixture level to keep the unit clean. Power units can also be mounted on the machine tool using an angle bracket. Connect to a fused electrical supply and fill with clean, approved Hydraulic Fluid. Do not use NPT fittings for hydraulic connections.

Safety Features

Fail-safe operation in case of electrical-power failure since the solenoid-operated clamping valves are de-energized in "clamped" position. These valves are poppet type, so they provide tight zero-leakage sealing. Pump motor has a thermal-overload relay with manual reset.

Duty Cycle

Electric Power Units are designed specifically and purely for workholding, with intermittent clamping and unclamping between machining cycles (not continuous running). For most workholding applications, actual running time is a small percentage of total cycle time. Run time must be less than 40% of total cycle time at maximum fluid level (25% at minimum fluid level). Run time must also be less than 120 continuous seconds at maximum fluid level (15 seconds at minimum fluid level). Otherwise the fluid will overheat and the unit will shut off automatically.

Parts Specification

| Operating Pressure Range (PSI) | Control Voltage | Valve Function | Includes Push- Button Pendant Switch | Flow Rate (cu In. /min) | Reservoir Capacity (cu In.) | Usable Fluid Capacity (cu In.) | Power At Max Pressure (hp) | Motor Current (amps) | Noise Level @ 3 Ft (dba) | Weight (lbs) |

| 1160 -7250 PSI | 24VDC | Two Independent Double-Acting Circuits | Yes (2) | 66 cu in. /min | 690 cu in. | 400 cu in. | 1.5 hp | 2.1 amps | 75 dBA | 110 lbs. |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order