MCP100Z 5-Axis Concentric Manual Vises (100mm)

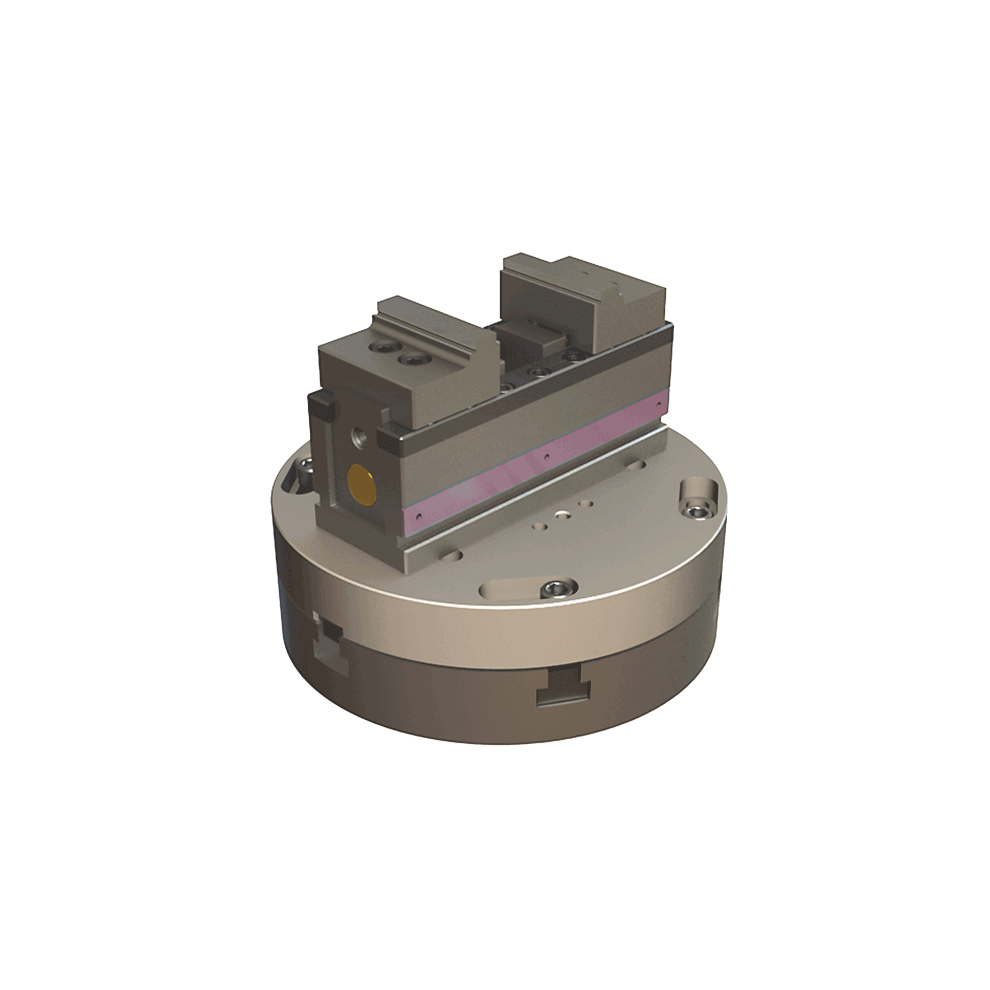

Mechanical OperationThe Z-series version of the MCP100 vise is dimensionally similar, but incorporates the precision self-centering mechanism. Concentric vises have two moving jaws that provide clamping at the exact center of the rotary table. The MCP100 Z vise is large enough to handle a wide range of workpiece sizes. Like all of the 5-axis vises, this vise has optimal features to allow unrestricted tool access for multiple-side machining. Finest-quality construction with a special cast steel base for excellent rigidity, dimensional stability, and durability. All sides are hardened and ground, providing a basis for maximum precision. Made in Germany.

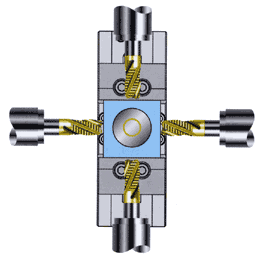

The MCP series is a further refinement of the high-precision MC vise series. These new vises combine a very compact, fully enclosed design with a patented sliding-jaw segment design. Thanks to the adjusting spindle arranged in the upper part of the housing, deformation in the base during clamping is reduced to a minimum, providing high rigidity of the entire workholding system. The patented segment design ensures a high degree of precision and stability, reducing guiding clearance to nearly zero.

Application Information

Unique design allows clear tool access to five-out-of-six workpiece sides.

Mounting on a Quintus 2 Riser

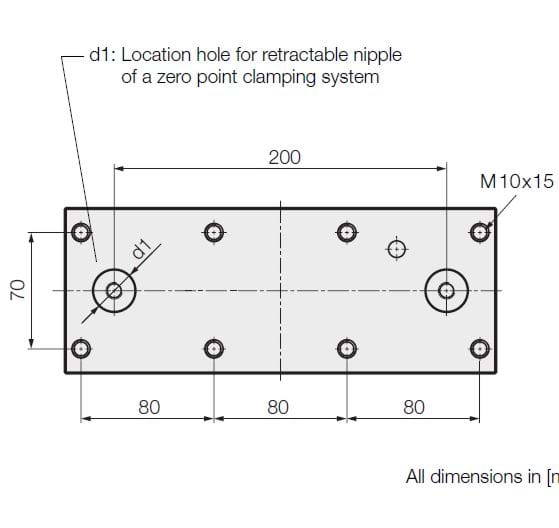

Before using the vise, install both Quintus 2 pull-down bolts in the vise's M10 counterbored bottom locating holes (order separately – see Dimensions page for part number). To locate and clamp the vise, the Quintus 2 riser utilizes these two pull-down bolts – #1 with zero-point centering, #2 with single-axis centering. First, turn Quintus mechanism #1, then turn Quintus mechanism #2. Each exerts 4500 lbs of force on its pull-down bolt.

Mounting on a Vise Adaptor Plate or Riser Block

To locate the vise, use two Fixture Locating Pins, a round pin for zero-point centering and a diamond pin for single-axis centering. To fasten the vise, use eight M10 x 35mm socket-head cap screws inserted through the plate from below.

Material

| Material | Heat Treat | Finish | DFARS | RoHS |

| Cast Steel | - | Hardened | Yes | Yes |

Parts Specification

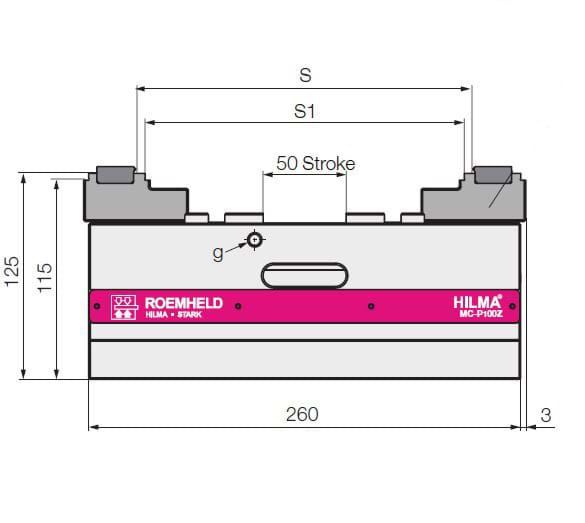

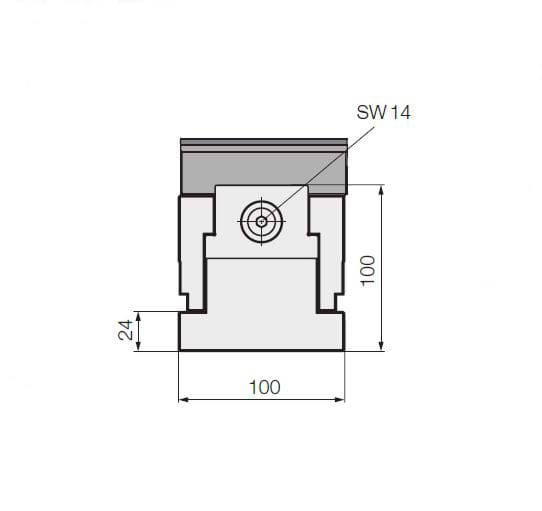

| Jaw Width (mm) | Clamping Force | Clampingstroke (mm) | Sjaw Opening (mm) | S1jaw Opening (mm) | D1 | G | Weightwithoutjaws (lbs) |

| 100mm | 5600 lbs at 59 ft-lbs(25 kN at 80 Nm) | 50mm | 18-204mm | 6-192mm | 25mm+0.01 x 5mmandM10 x 14mm | M8 x 14mmBoth Sides | 39 lbs. |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order