Aether Machining saves time, money by switching to Helical Solutions cutting tools

Posted by All Industrial Tool Supply on Sep 09, 2021

Working faster. Less waste. Higher quality. Lower costs.

Any business owner or shop manager would dream of having just some of those results when changing a machining process. For Aether Machining of Anaheim, California, all those dreams became reality, thanks to an audit of their needs performed by Nate Craine, Field Sales Engineer from All Industrial Tool Supply, and our partners at Helical Solutions.

Aether Machining

From their home in Orange County, Aether Machining manufactures custom CNC machined parts in a variety of dimensions and materials. Aether specializes in 3 and 4 Axis precision machining of aerospace parts, a demanding industry where quality, accuracy, and turnaround are critical.

Priding themselves on handling all aspects of a customer’s needs and providing a quick turnaround, Aether has been an All Industrial customer since 2020 and we’re delighted to help support them in their business by providing the tooling and guidance they need for productivity.

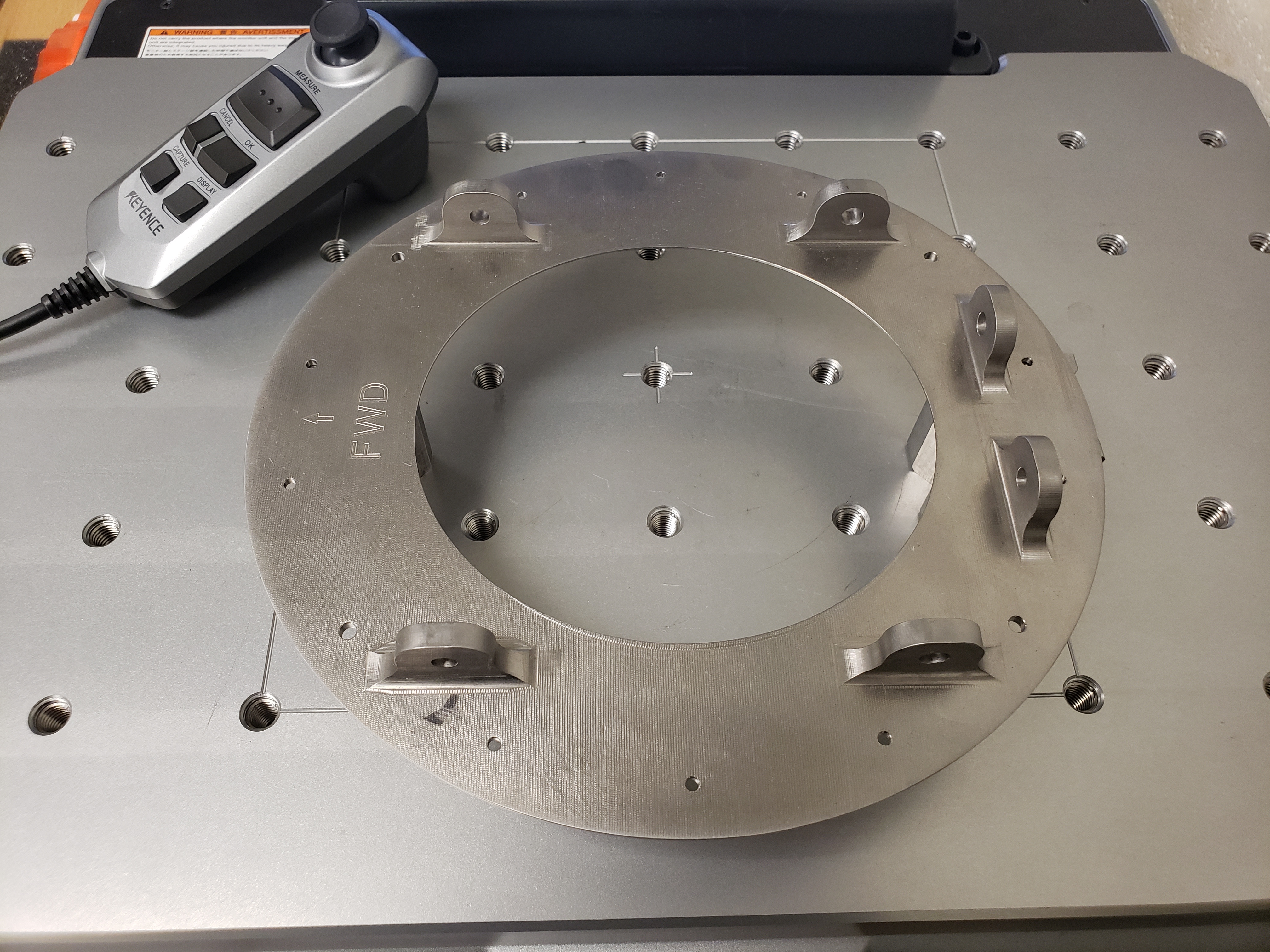

An example of Aether’s machining work

A project in 6/4 (Ti-Al6-V4) titanium

Aether undertook a particularly difficult project to produce 300 parts, executed in 6/4 Titanium - known for being a challenging material that is notoriously hard on tools.

Using their current “famous-maker” tool supplier required 1 tool per part, so it would require 300 cutting tools to complete the job. After reviewing the requirements, we recommended using the Helical Solutions 82075 Carbide Corner Radius End Mill for Titanium as a higher-performing and longer life alternative.

Using the Helical 82075 allows the same job to be completed with half the number of tools - just 150. It has a longer life, as well as a much faster surface speed and RPM - achieving 4x the material removal rate, so Aether works faster too.

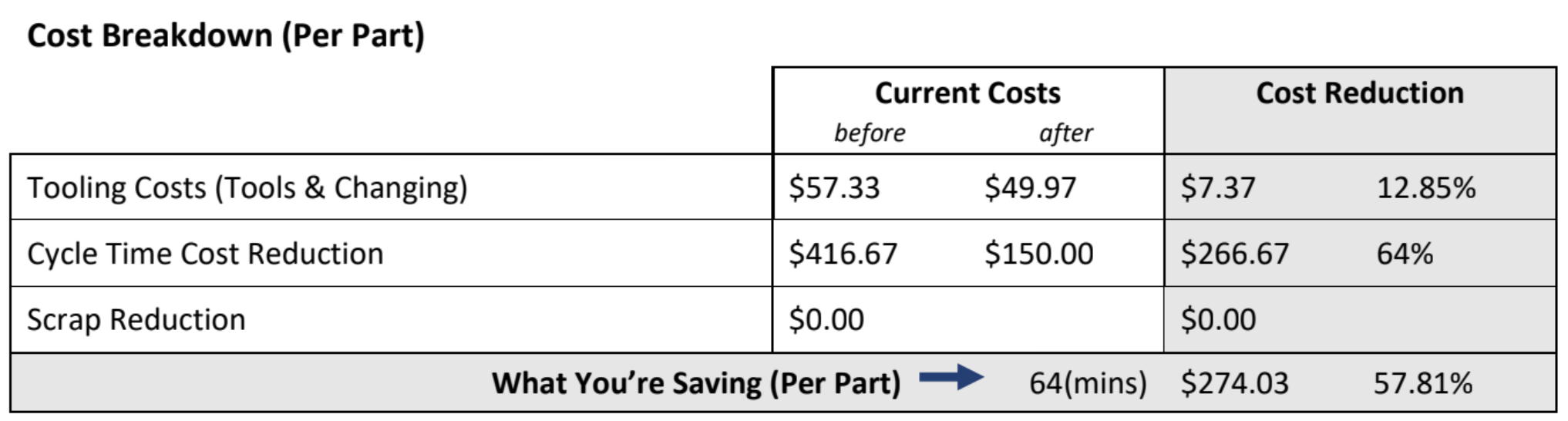

Cost savings from reduced tooling cost and cycle time improvements

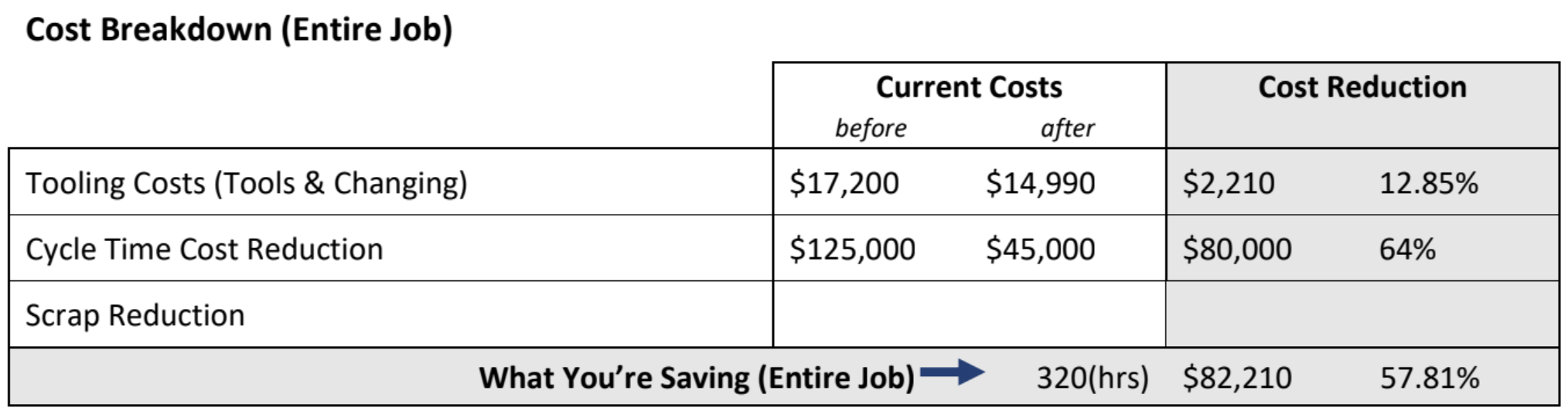

By switching to the Helical Solutions mill for this project, Aether Machining realized savings of 64 minutes and $274.03 per single part produced, and more than 320 hours and $82,000+ over the entire job (300 finished parts). This cost and time savings required nothing more than switching to a higher quality tool that was more appropriate for the job and making sure it was run at the correct speeds and feeds.

Aether realized a savings of $274.03 per part produced:

...and a savings of $82,210 over the entire job!

“The cost and time savings presented by Helical Solutions are clear”, says Cristian Aguilar, President of Aether Machining. “Making the change was a no-brainer, and I’m pleased with the results.”

Save time and money on your next project

All Industrial Tool Supply has the knowledge and expertise to help you realize this type of cost and time savings in your shop. Call (714) 897-1700 or email the sales team at All Industrial Tool Supply for a free analysis and recommendations suited to your specific requirements.

714.897.1700

714.897.1700

Chat

Chat

Email

Email

844.548.0100

844.548.0100

Quotes

Quotes

Quick Order

Quick Order