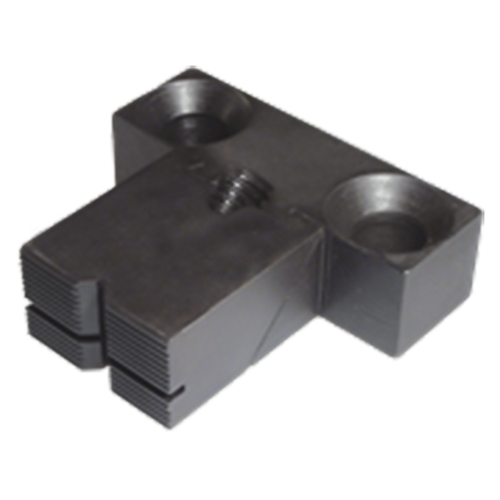

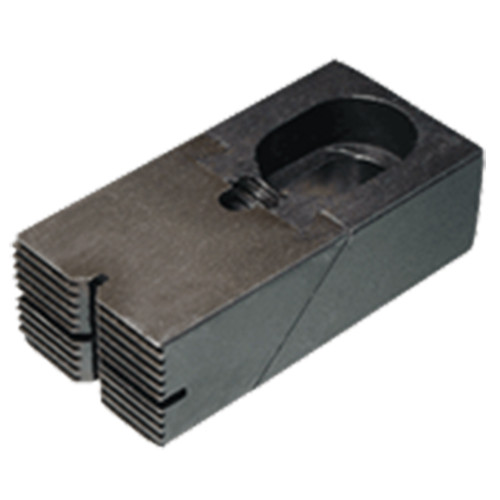

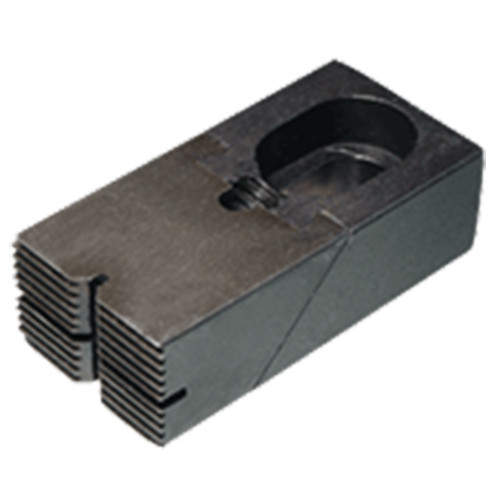

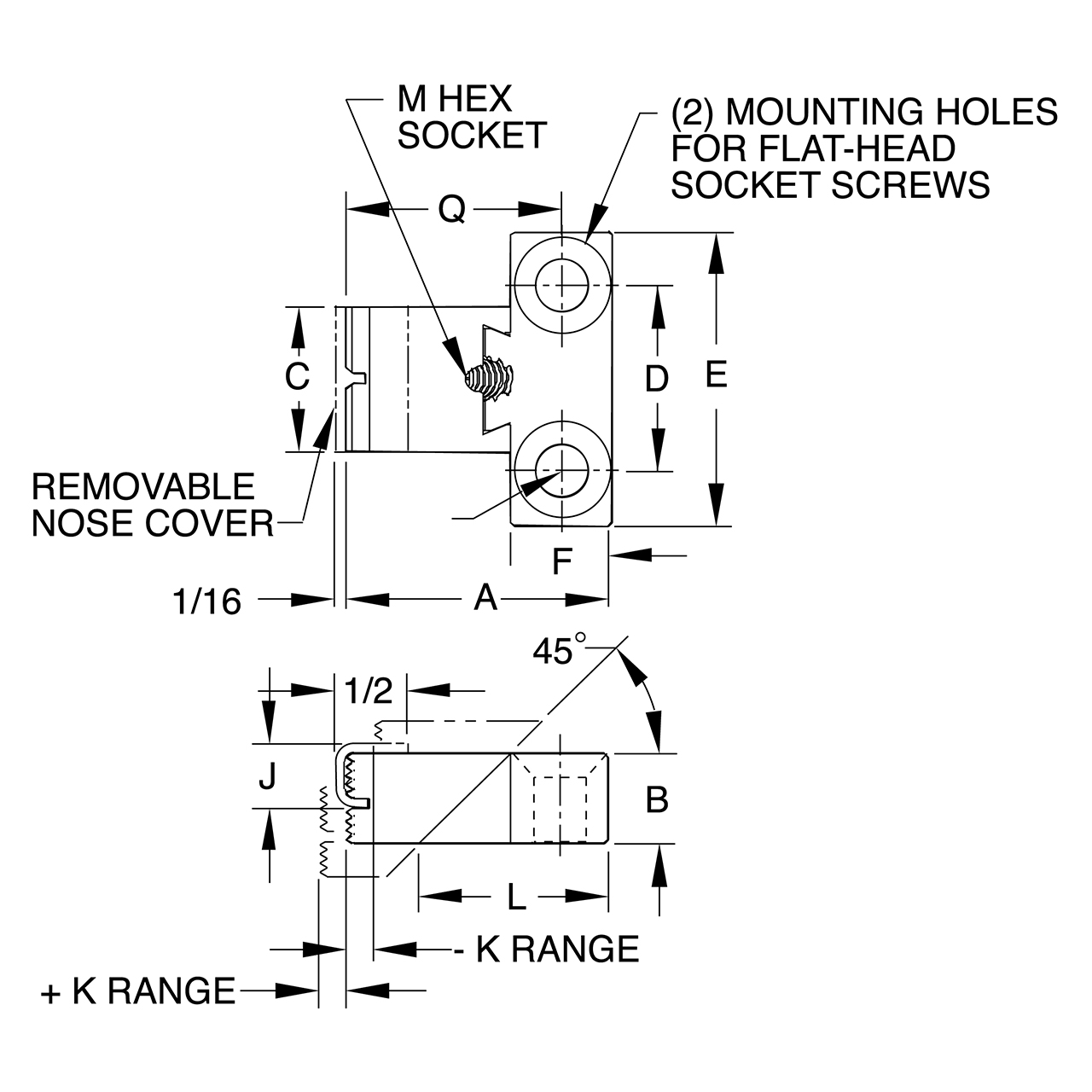

Serrated Fixed Edge Clamps

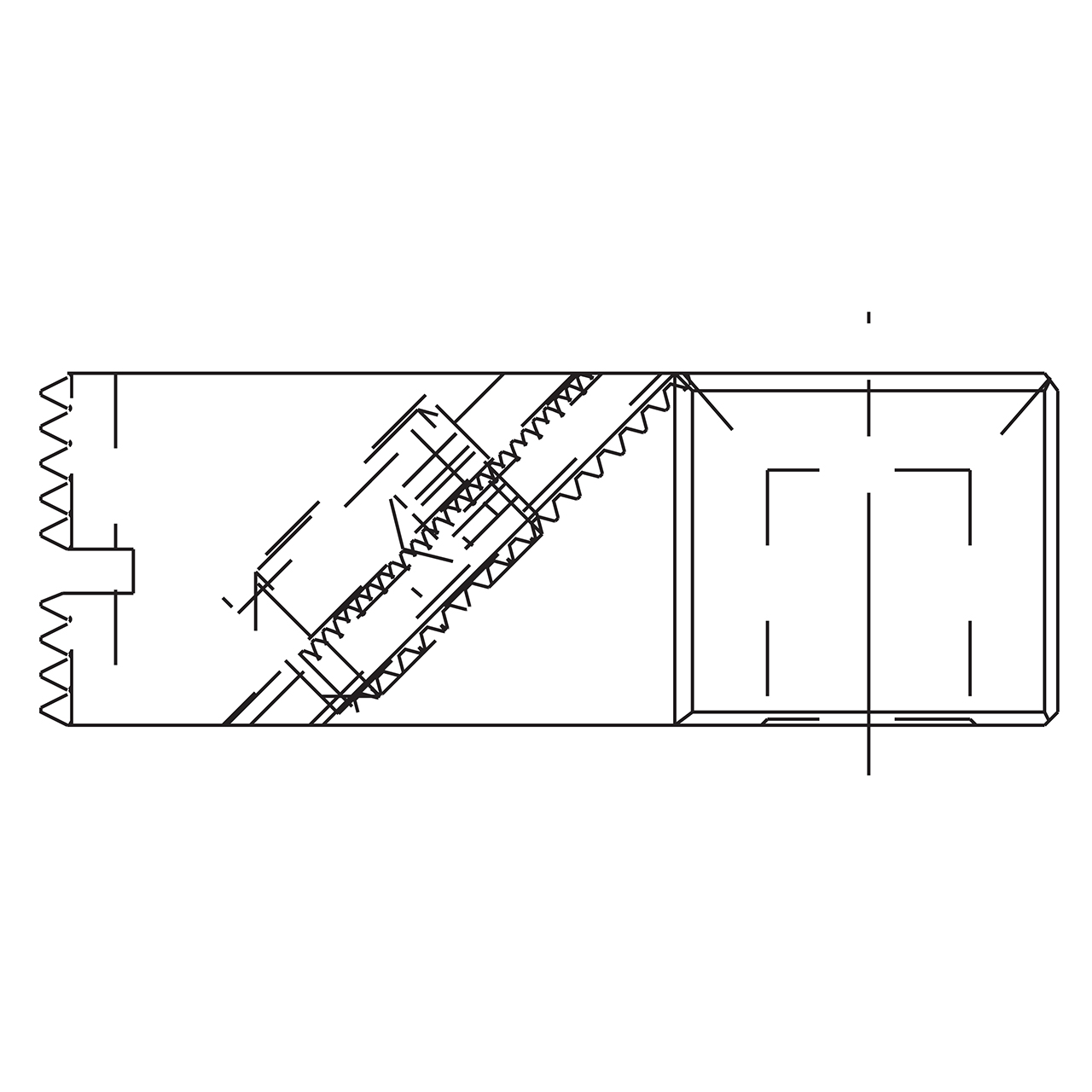

These low-profile clamps are ideal for securely gripping the side of a workpiece to keep the top clear for machining, especially when a large clamping range is required to accommodate workpiece-size variations. The serrated jaw slides at a 45° angle to exert clamping force both forward and downward simultaneously. Clamp by turning the socket-head screw in the sliding nose with a hex wrench. V-groove in nose is useful for clamping round parts or corners.The fixed edge clamps shown here are ideal for permanent fixtures, because they have two fixed mounting holes instead of a slot. This allows the clamp to be more compact, and ensures correct position without adjustment.

High-Nose Version

The high-nose version shown here is best for most applications-gripping high on the workpiece, close to the machining plane, to provide maximum clamping rigidity. This version includes a removable aluminum nose cover for clamping soft or machined parts without damage.

Material

| Item | Material | Heat Treat | Finish | Heat Treat | Finish |

| Body and Nose | 1018 Steel | Carburized Hardened | Black Oxide | Yes | Yes |

| Clamping Screw | 4140 Steel | Heat Treated Rc 43-45 | Black Oxide | Yes | Yes |

Parts Specification

| Mounting Screw Size (Inch) | A (Inch) | B (Inch) | C (Inch) | D (Inch) | E (Inch) | F (Inch) | J (Inch) | K (Inch) | L (Inch) | M (Inch) | Q (Inch) |

| 5/16-18" | 1-27/32" | 5/8" | 1" | 1" | 1-3/4" | 11/16" | 7/16" | 1/4" | 1-5/16" | 5/32" | 1-1/2" |

Warning:

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

For more information, visit www.P65Warnings.ca.gov

714.897.1700

714.897.1700

Chat

Chat

Email

Email

Quotes

Quotes

Quick Order

Quick Order